WHX 2026

Join Vermon at WHX 2026, in Dubai, UAE, from February 9 to February 12, North Hall 21, K.92.

Dubai, UAE

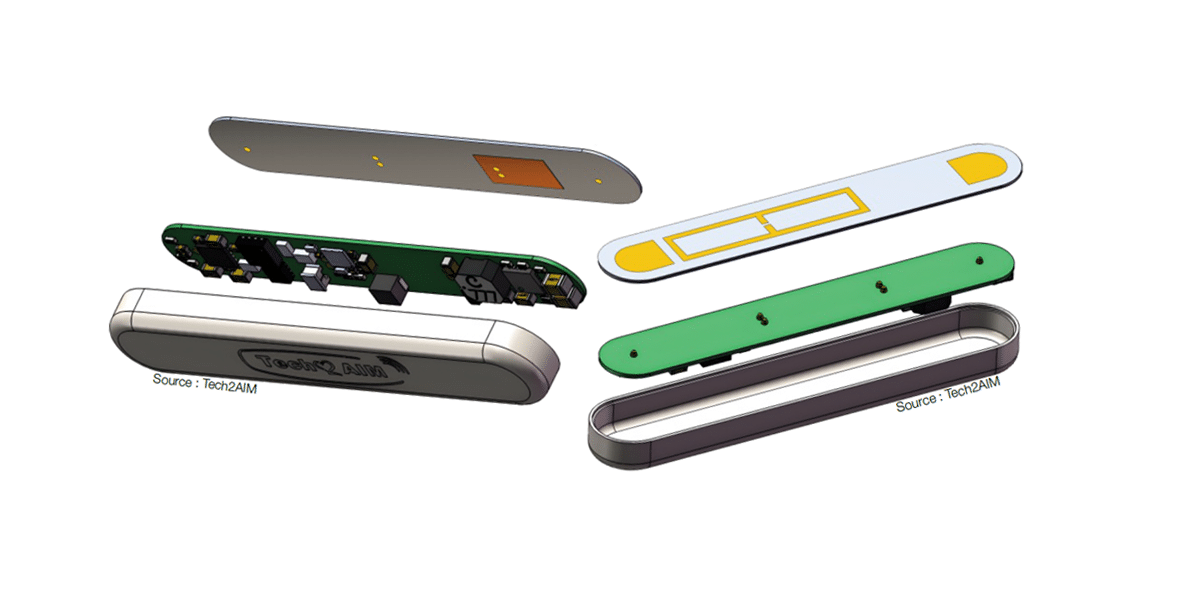

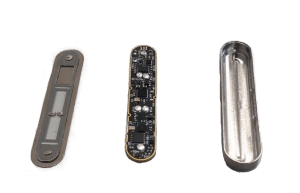

Two industrial companies: Mistic & Vermon and two technical research centers: CRESITT & GREMI from the French Centre Val de Loire region have combined their efforts and expertise in the TECH2AIM project (Turnkey Technologies to enable next generation Active Implantable Medical devices). The objective: to develop innovative technological building blocks implemented in a demonstrator of an implantable cardiac monitor.

Active implantable medical devices (AIMDs) are designed to be implanted in the human body for more than 29 days with an active role in detection and/or treatment. Common examples include pacemakers, cochlear implants, neurostimulators, insulin pumps, gastric stimulators, and many others. The AIMD market is evolving rapidly, especially due to the diversity of therapies that have accelerated over the past decade. Neurostimulation, for example, is now studied and applied to many organs of the human body. Historically, most AIMDs have had a therapeutic purpose, but diagnostics and prevention applications, such as implantable ECG recorders, are experiencing exponential growth. This is mainly due to advances in miniaturization and more sophisticated algorithms.

The new generations of AIMDs focus on three main development axes:

To meet these increasingly ambitious, sometimes contradictory objectives, and to overcome the conventional physical architecture of devices, new technological solutions are needed.

A Regional Consortium for New Technological Solutions

Recognizing this, a regional consortium has been formed to develop technological building blocks dedicated to the specific needs of miniaturization, communication, and extended lifespan. It consists of two industrial players (Vermon & Mistic) and two technical partners (CRESITT & GREMI) who collaborate within the TECH2AIM project, a project funded by the Centre Val de Loire region and BPI France. Vermon and Mistic are developing these groundbreaking solutions to offer to future AIMD manufacturers. To establish the credibility and functionality of the components, the project aims to design an ILR (Implantable Loop Recorder) platform as an implantable continuous heart rate monitoring demonstrator.

This demonstrator integrates three technological building blocks:

The technical centers provide complementary expertise: deep plasma etching of high aspect ratio titanium for GREMI, and the design and characterization of an RF antenna, as well as all associated control electronics, firmware and energy management for CRESITT.

Successful Completion of the Conceptual Phase

Two years after the launch of the consortium and the TECH2AIM project, the conceptual phase has been successfully completed, and the technological building blocks are being assembled for final integration.

The Project Actors: Perfect Complementarity of technological know-how

Vermon : Specialized in manufacturing ultrasonic transducers and ultrasound probes for medical and industrial applications. Their R&D focuses on piezoelectric and MEMS technologies including beyond imaging applications: vibrational energy harvesting and wireless ultrasonic energy transfer.

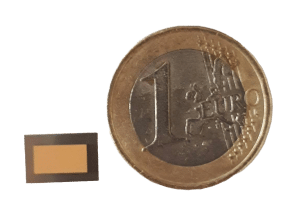

Mistic : Transfers micro and nanotechnologies based on silicon substrates to titanium wafers to develop MEMS (Micro Electro Mechanical Systems). The resulting functional titanium chips are intrinsically biocompatible. They are also engaged in creating implantable feedthroughs for AIMDs.

CRESITT Industrie : A Technology Resource Center (CRT) in Orléans, particularly skilled in embedded electronics. They conduct expertise, design proofs of concept, and pre-qualification of products in EMC and RF. Their role in the consortium is to support the development of Vermon and Mistic’s technological components in terms of energy transmission management electronics and RF antenna design.

GREMI : A Joint Research Unit of the University of Orléans and the CNRS, focusing on plasma and laser applications like deep titanium etching. For the TECH2AIM project, they develop high aspect ratio etching processes for the titanium RF antenna integrated into the AIMD casing.

Advantages of the Consortium’s Approach

The approach adopted by the consortium allows these functionalities to be directly integrated into the hermetically sealed titanium casing of the AIMD. Each component is developed or transferred from collective manufacturing technologies on titanium substrate disks (“wafers”). Similar to semiconductors and MEMS, each wafer simultaneously produces multiple identical systems in an industrial environment proven for quality and reliability. The components can then be individually singulated and laser welded to the titanium casing, as commonly done in the AIMD industry for hermetic encapsulation.

“The only way to reduce the footprint of an AIMD while maintaining or increasing its intelligence is to functionalize its packaging and eliminate volumetric elements that are often difficult to industrialize,” explains Bertrand Boutaud, CEO and founder of Mistic. “For current and future clinical needs, we are moving towards miniaturized and ultra-thin AIMDs, similar to how 20th-century cathode ray tube televisions have given way to flat screens.”

Conclusion

The TECH2AIM project marks a significant step towards the next generation of AIMDs with enhanced functionality, miniaturization, and longevity, benefiting both patients and the healthcare system.

Source

This article is translated from French article “Un projet régional avec l’ambition de préfigurer les DMIA de demain” published in Devicemed magazine, September/October 2022

References

R Ettouri, T Tillocher ,P Lefaucheux, et al. “Combined analysis methods for investigating titanium and nickel surface contamination after plasma deep etching“, Surf Interface Anal. 2022; 54(2): 134-147

T Hoang, B Rosinski, N Felix, “Implantable medical device and method to manufacture such a device“, US20230420995A1

T Hoang, B Rosinski, N Felix, “System to recharge an implantable medical device“, US20240009471A1

T Hoang, B Rosinski, N Felix, “Ultrasound transducer optimization for wireless battery charging in subcutaneous implantable device“, 2022 IEEE International Ultrasonics Symposium (IUS)

Transducer enabling the implant’s battery to be recharged using ultrasound.

WHX 2026

Join Vermon at WHX 2026, in Dubai, UAE, from February 9 to February 12, North Hall 21, K.92.

Dubai, UAE

Read More

EcoVadis Gold Medal 2025: Vermon Among the Top 5% of Rated Companies

Vermon has been awarded the EcoVadis Gold Medal 2025 for the second consecutive year, recognizing its strong commitment to Corporate Social Responsibility. This distinction places Vermon among the top 5% of companies worldwide, highlighting its continuous efforts in sustainability, ethics, and responsible business practices.

Read More

Vermon Wins the INPI Export Award 2025 for Innovation and Intellectual Property

Vermon has been awarded the INPI Export Award 2025, recognizing the strength of our intellectual property strategy and its role in supporting the international development of our high-performance ultrasound technologies. This distinction highlights Vermon’s contribution to French medical innovation and its global impact in the field of medical ultrasound and diagnostic imaging.

Read More

Multidisciplinary Group Awarded in France 2030 Plan to Develop Next-Generation Software-Based, Smart, and Frugal Ultrasound Imaging Devices

The POCUSI (Point of Care UltraSound for Screening & Intervention) consortium—bringing together E-Scopics, Vermon, IHU Strasbourg, and Inria—has been awarded funding under the France 2030 investment plan to develop a new generation of software-based, intelligent, and frugal ultrasound imaging devices.

With a total budget of €6.7 million over five years, the project aims to democratize point-of-care ultrasound, making advanced imaging accessible to non-expert operators throughout the patient care pathway. POCUSI focuses particularly on chronic liver diseases and metabolic disorders, enabling improved screening, monitoring, and image-guided interventions. By combining cutting-edge software, high-performance probes, clinical expertise, and data-driven simulation tools, POCUSI supports the emergence of a strategic and sustainable French digital ultrasound sector, strengthening France’s technological sovereignty in medical imaging.

Read More

RSNA 2025

Join Vermon at RSNA 2025 in Chicago, USA, from November 30 to December 4. Discover our latest ultrasound transducer innovations and meet our team in North Hall, Level 3 – Booth 8049.

CHICAGO, USA

Read More