CMUT & PMUT Technologies

Advanced MEMS Technology

With more than 20 years experience in MEMS technology, Vermon offers robust solutions in both Capacitive Micromachined Ultrasound Transducers (CMUT) and Piezoelectric Micromachined Ultrasound Transducers (PMUT).

Our dedication is to support your MEMS projects from concept through to industrialization, adapting to the various stages of product maturity with a comprehensive suite of engineering services.

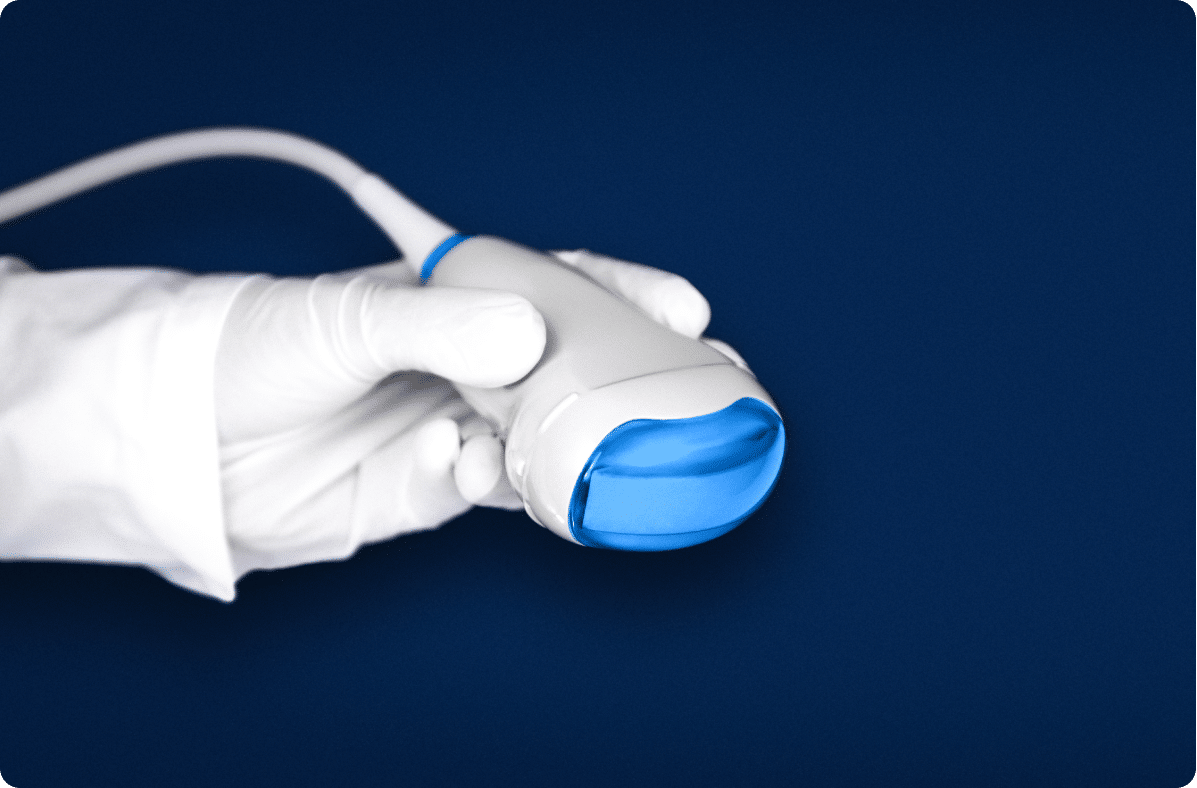

Innovative Design for Medical Imaging

Today’s ultrasonic transducers for medical imaging are predominantly based on poly- or single-crystalline piezoelectric ceramics and composites.

These materials have become the standard in medical imaging due to their high dielectric constant and high electromechanical coupling coefficient.

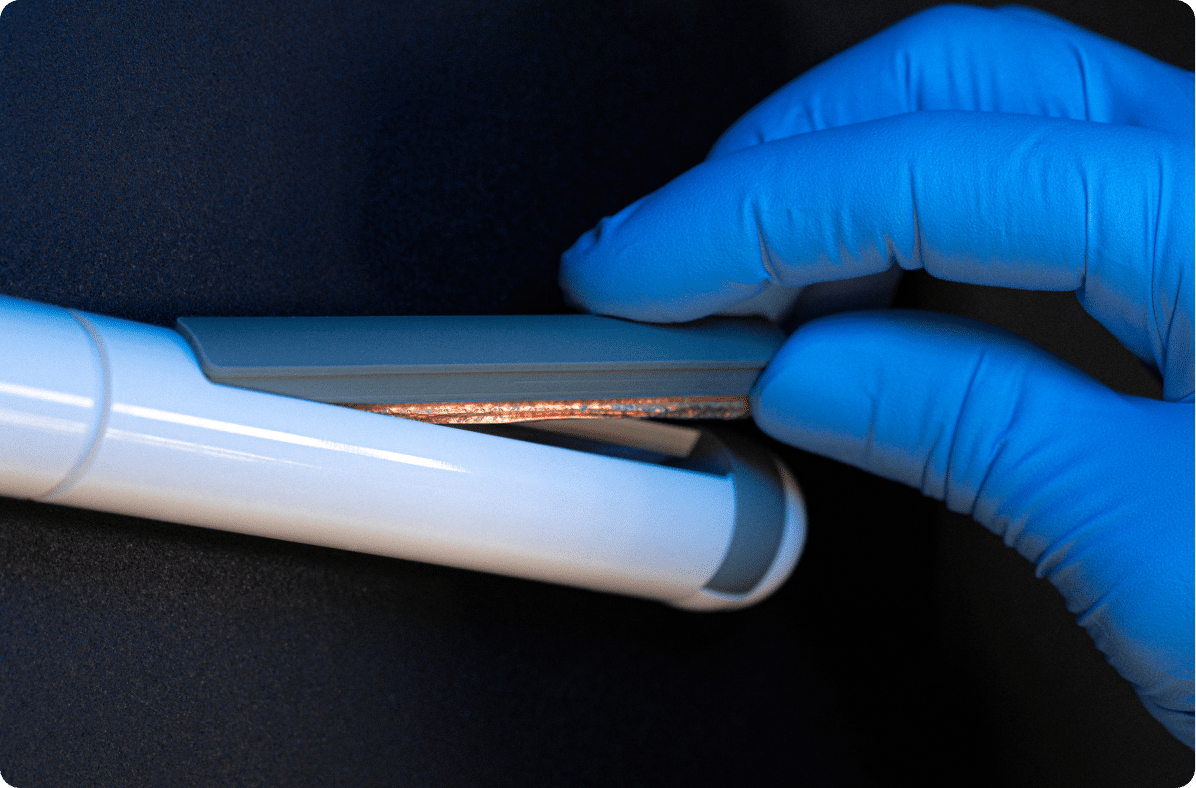

Unlike these traditional materials, MUTs can be manufactured using standard microfabrication technologies. This not only significantly reduces the costly assembly steps required for conventional piezoelectric transducers but also enables miniaturization and supports high-frequency broadband operation.

CMUT and PMUT Technologies

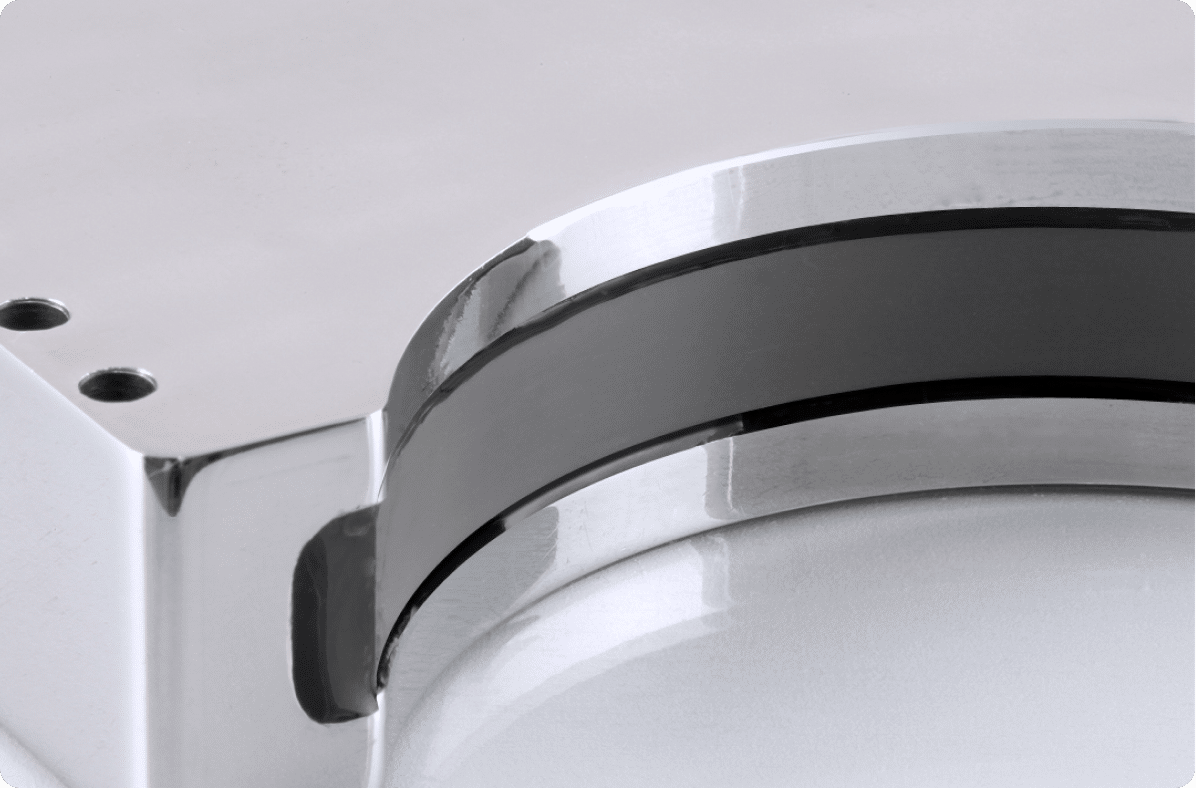

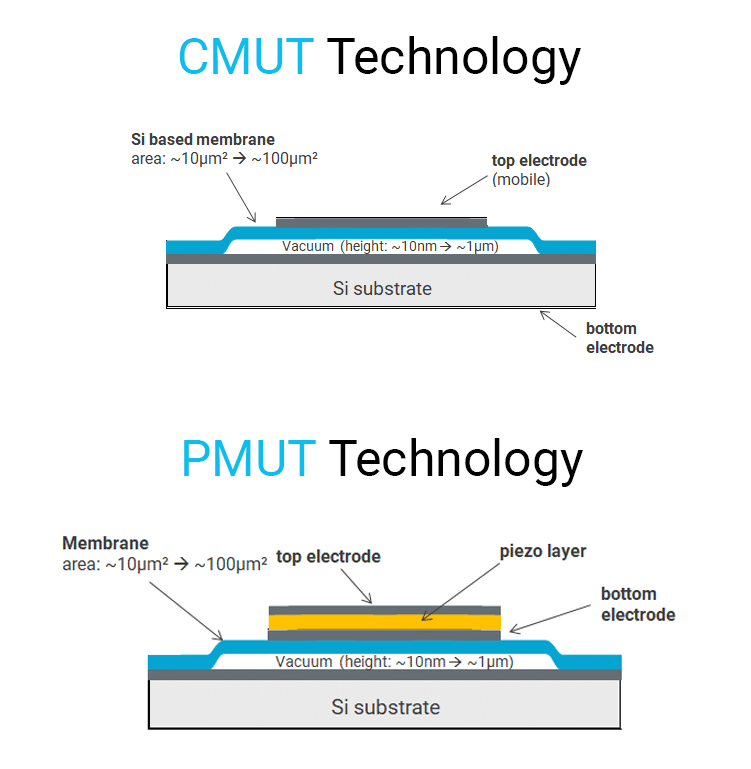

A MUT consists of a thin membrane suspended above a cavity.

The CMUT utilizes an electrostatic effect, while the PMUT operates on a piezoelectric effect.

Unlike traditional piezoelectric transducers, MUTs vibrate in a flexural mode, offering lower mechanical impedance and better acoustic matching to biological tissues without the need for additional matching layers.

- CMUT: Features a conductive layer on the vibrating membrane, using electrostatic forces to create and detect acoustic waves, which enhances the electro-mechanical transduction efficiency and allows precise control over a wide range of operating frequencies.

- PMUT: Utilizes a multi-layered piezoelectric thin film to produce and detect acoustic signals. This technology allows for high transmit capabilities and is optimized for detecting fine details, crucial for advanced medical diagnostics.

Overview on Vermon MUT technologies

The choice of the transducer technology is dependent on the targeted application and its business model.

Based on its strong experience on ultrasound devices (performances, manufacturing), our team is able to help our customers make the best choice for their product and application.

| CMUT | PZT PMUT | ALN PMUT | |

|---|---|---|---|

| Acoustic |

|

|

|

| Assy |

|

|

|

| Misc. |

|

|

|

Vermon MEMS Transducer Technical Value Chain

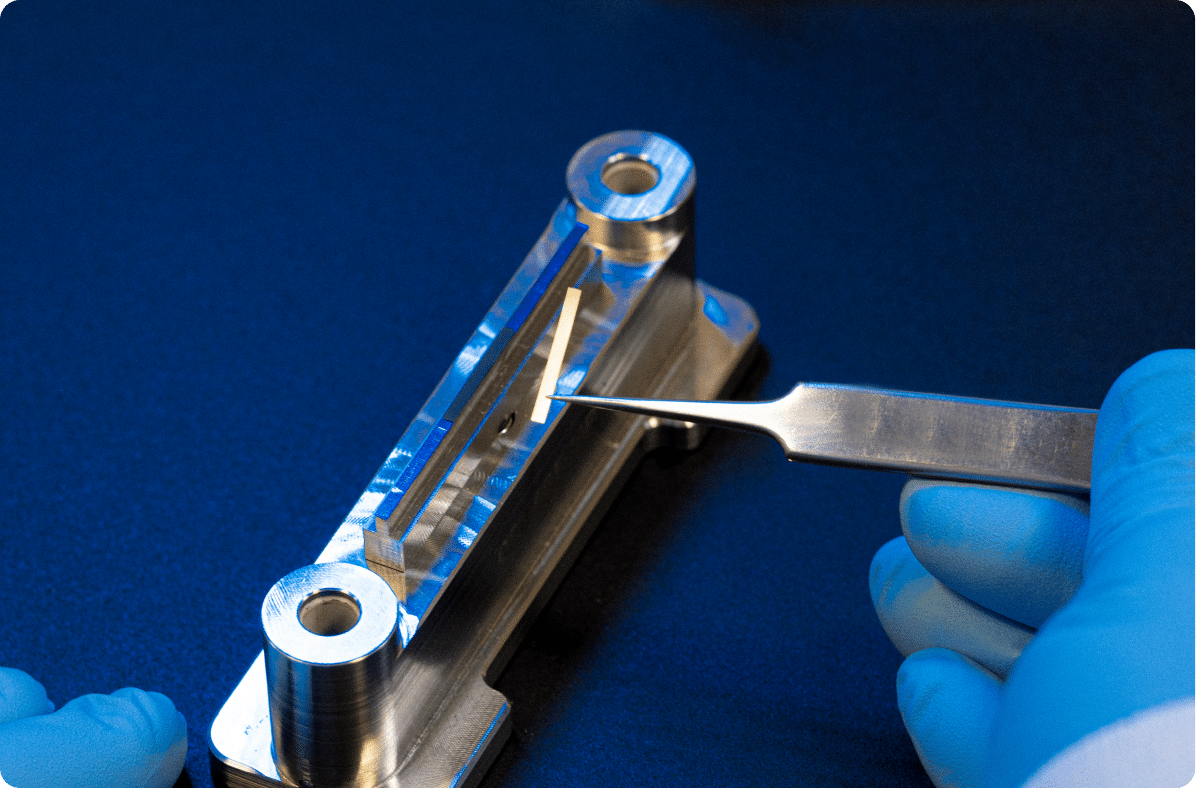

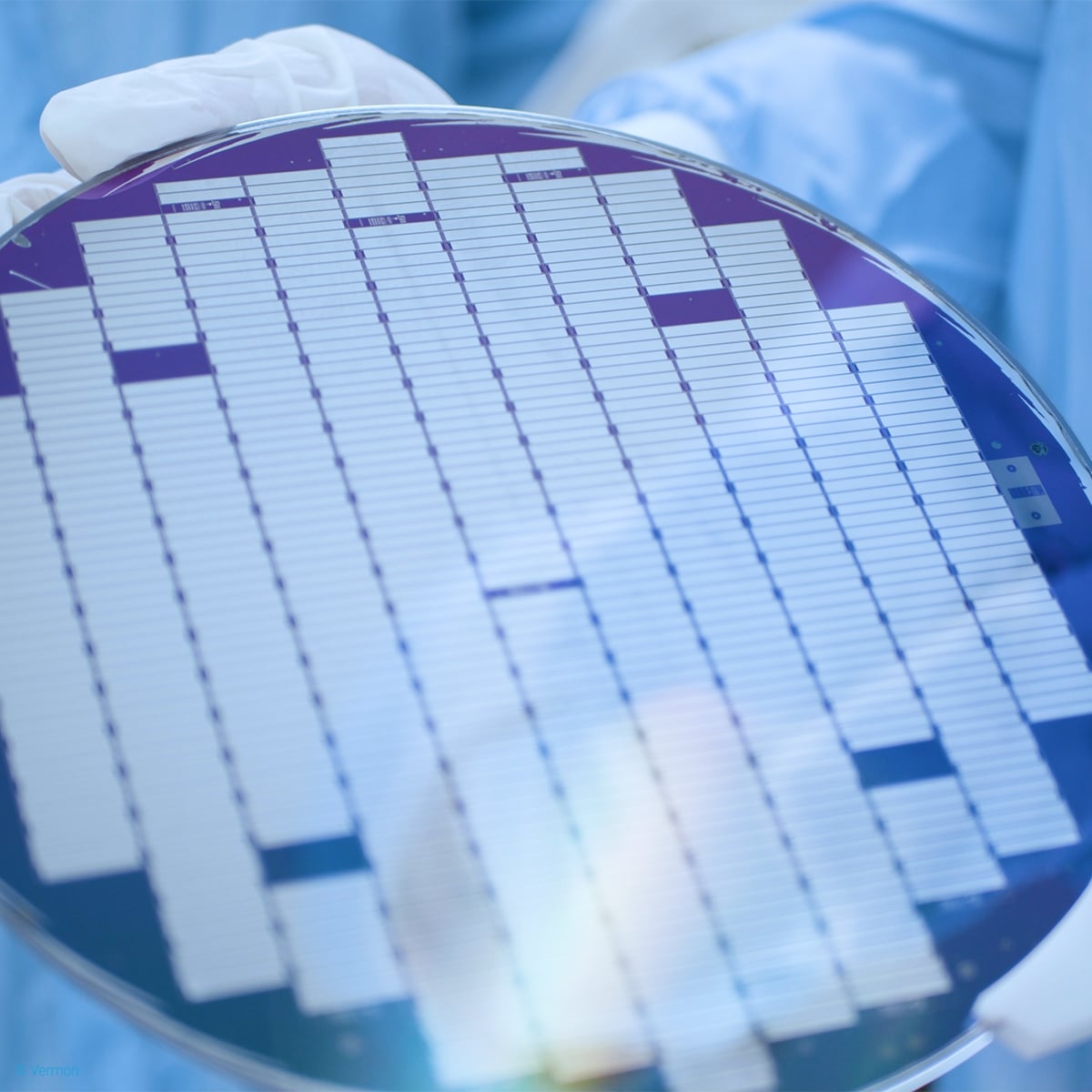

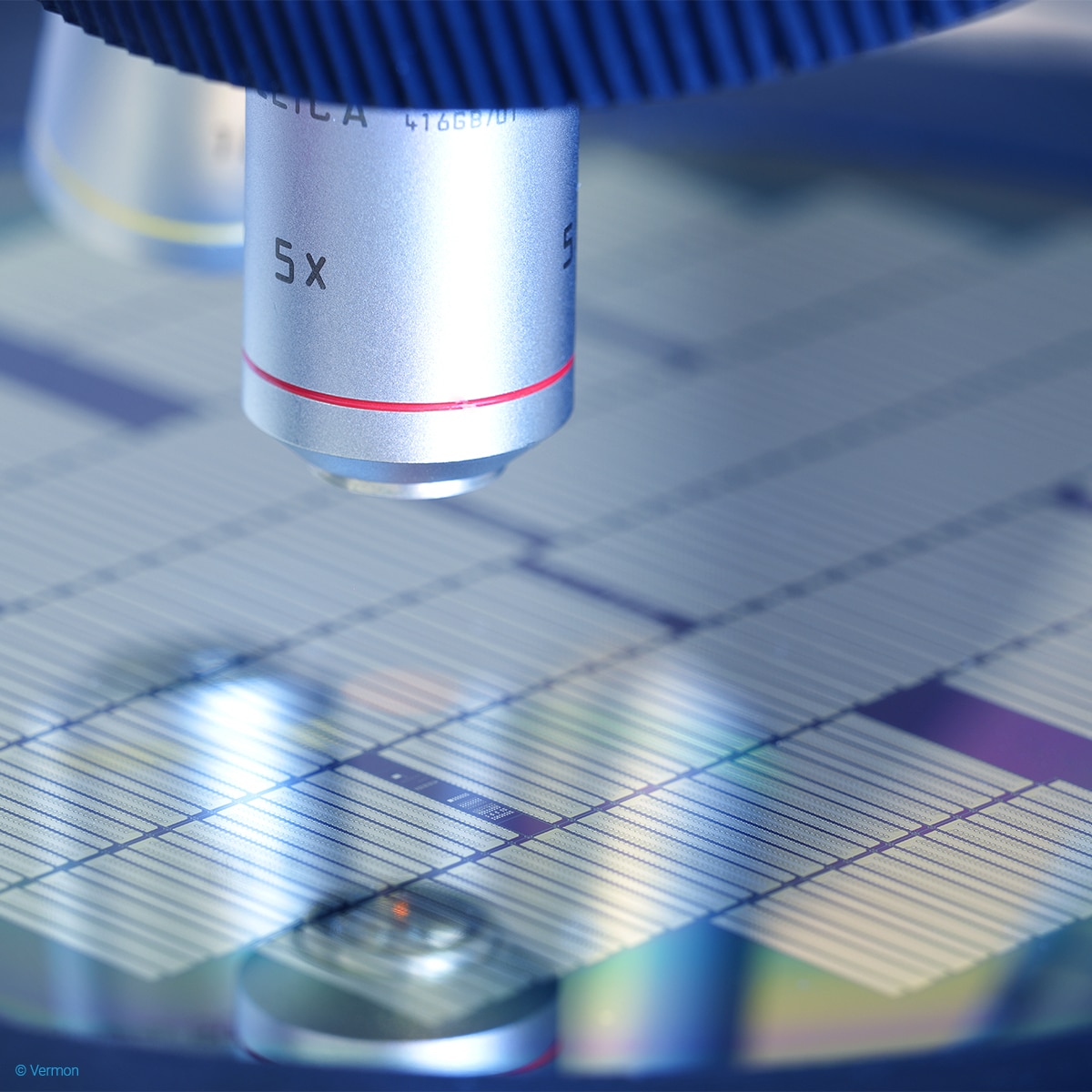

Vermon’s advanced manufacturing process, based on 8” wafer foundry lines, enables custom configurations from single-element transducers to complex 2D arrays, ensuring that our technology can be tailored to meet the specific needs of diverse applications.

Our capabilities include:

- Development and Specification: We handle all stages from the initial development of the ultrasound probe to detailed transducer performance specifications.

- Integration and Assembly: Our integration and assembly capabilities ensure that each component functions seamlessly within your system.

- ASIC Development and Support: In collaboration with external partners, we offer complete ASIC system architecture and development services.

For further details or inquiries, please do not hesitate to contact us.