OEM USB PROBE

OEM Solution for Active USB Ultrasound Probes Powered by Pulsarus™ Software.

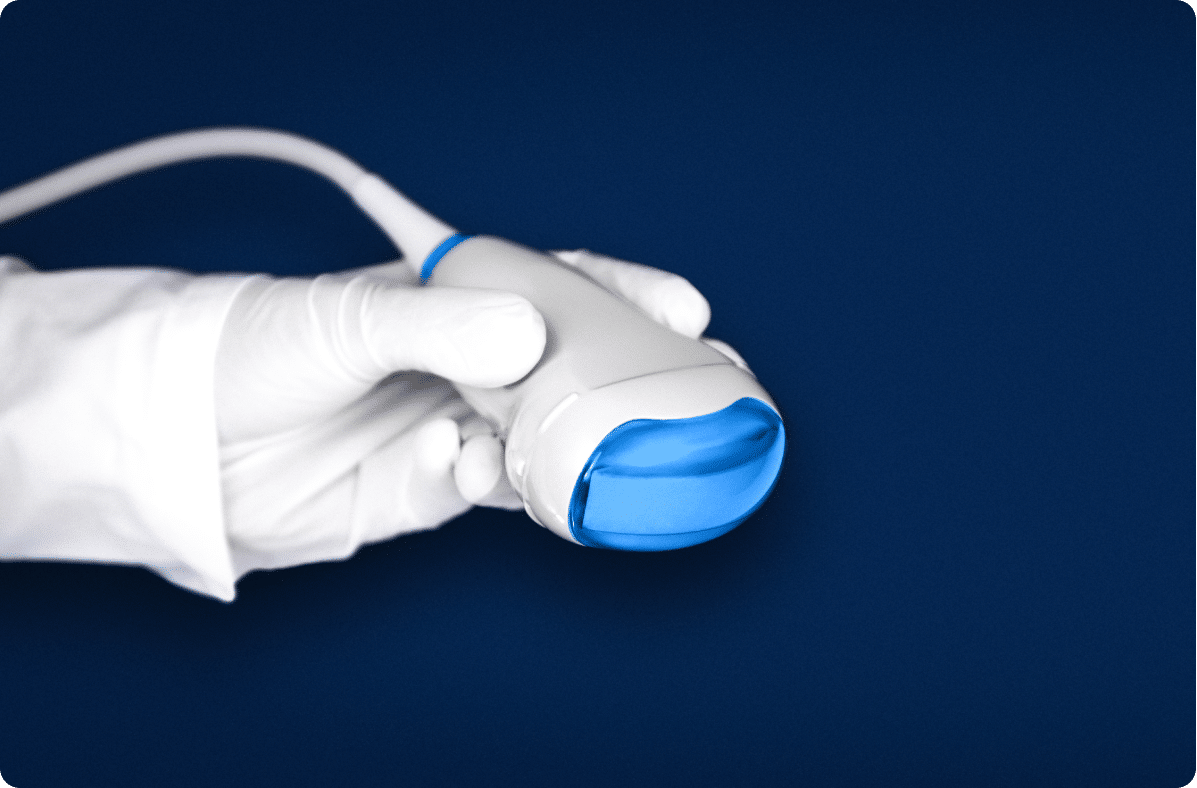

Our OEM USB probe offers a versatile solution suitable for numerous standard ultrasound applications – from curved arrays for abdominal imaging to phased arrays for cardiology, and linear arrays for superficial and vascular imaging.

Equipped with PULSARUS software, the OEM USB probe becomes an integral first step in the development of your ultrasound-based products.

Accelerate from idea to product with early proof of concept

Our OEM USB probe is an off-the-shelf solution crafted to seamlessly integrate ultrasound capabilities into your project or product development initiatives.

It meets the demands of emerging ultrasound application fields, including robotic surgery, guided therapy, biomarker measurement, and ultrasound guidance.

No matter the stage of your product development cycle or the specific ultrasound application you’re targeting, our OEM USB probe and Pulsarus™ are designed to meet your needs.

Vermon’s team of experts will guide, support and assist at every stage of the development process.

With our OEM USB probe, you can explore, test, and validate ultrasound features swiftly, ensuring a seamless proof of concept phase.

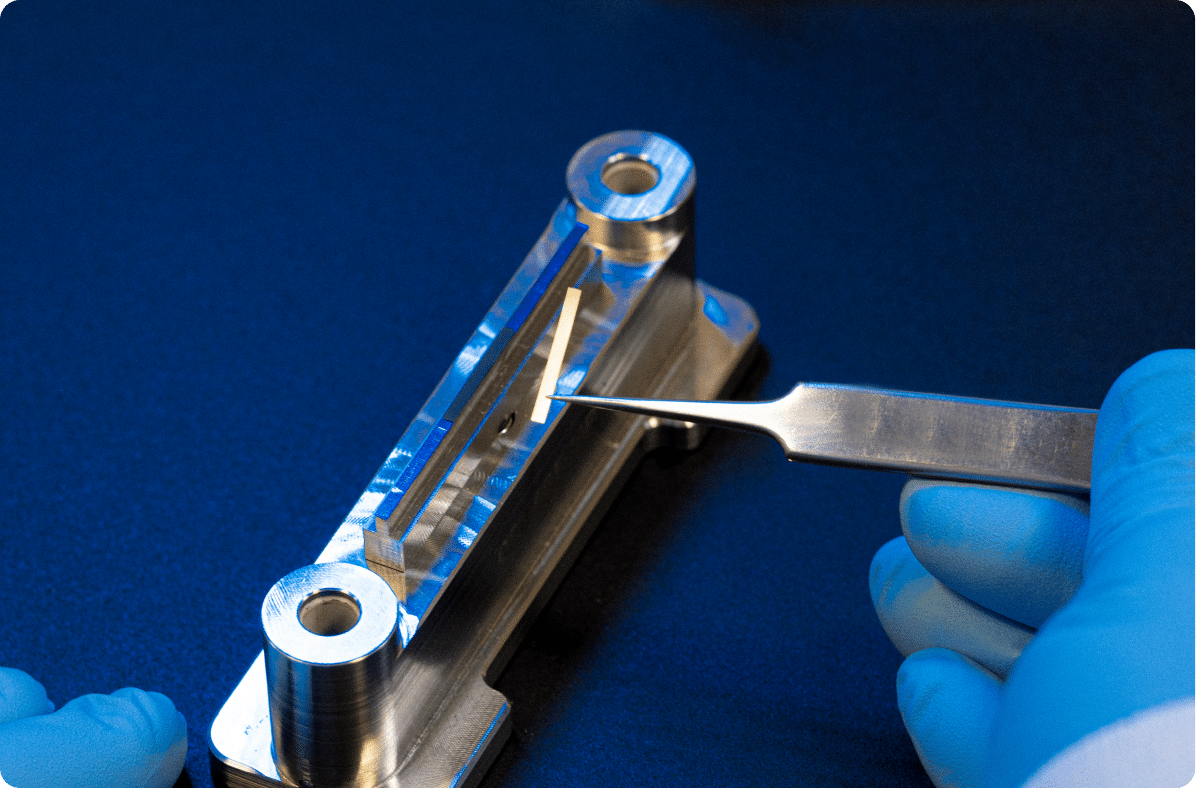

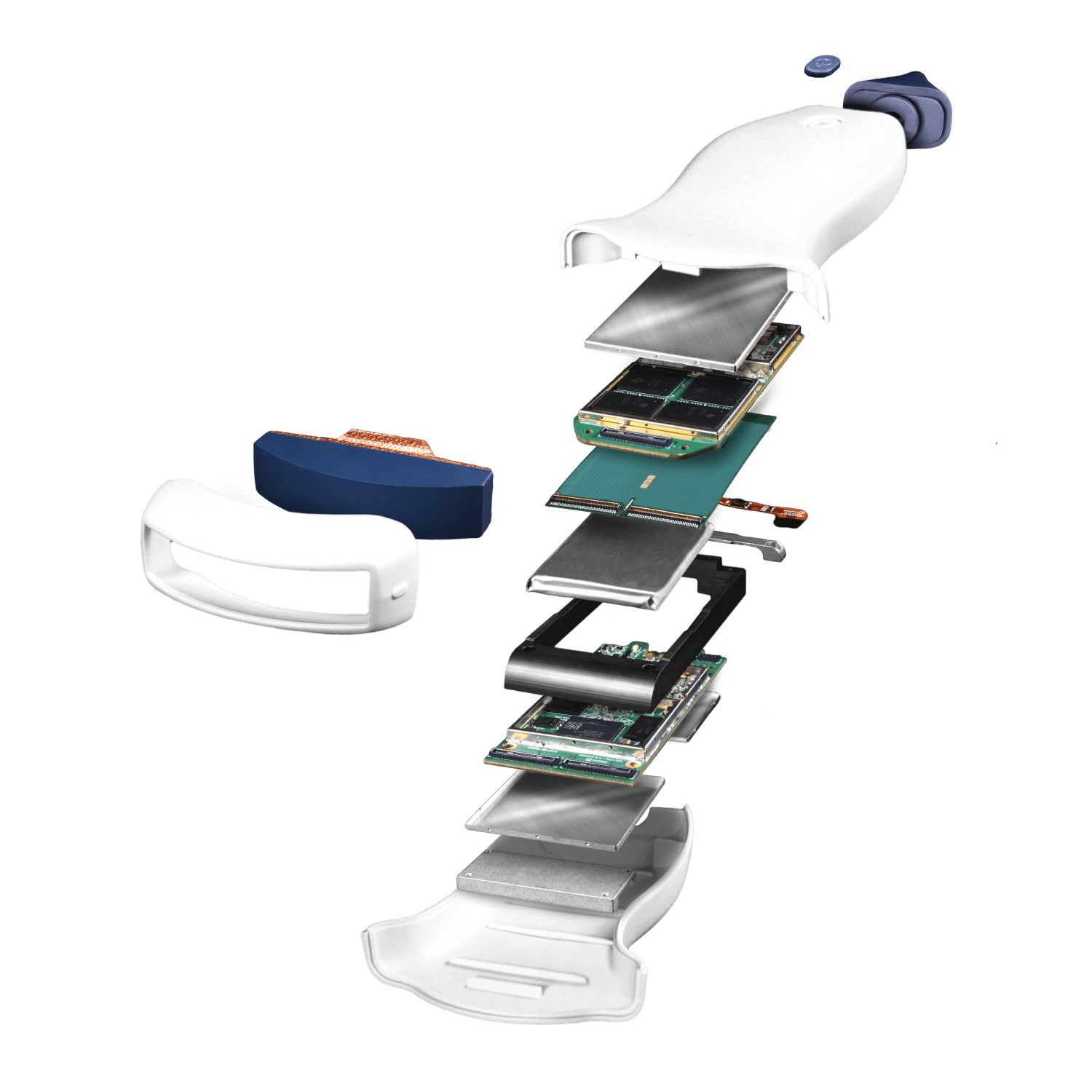

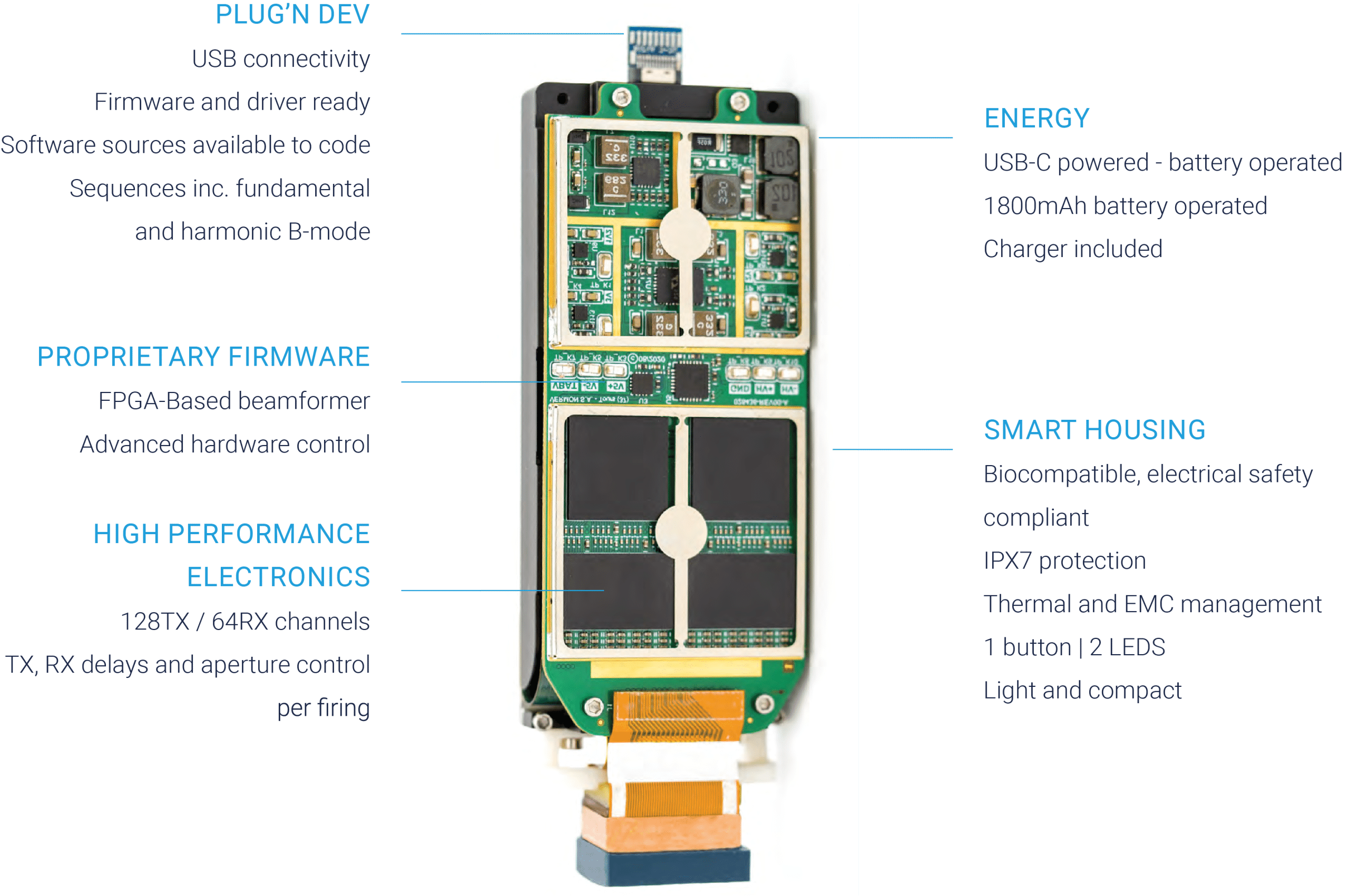

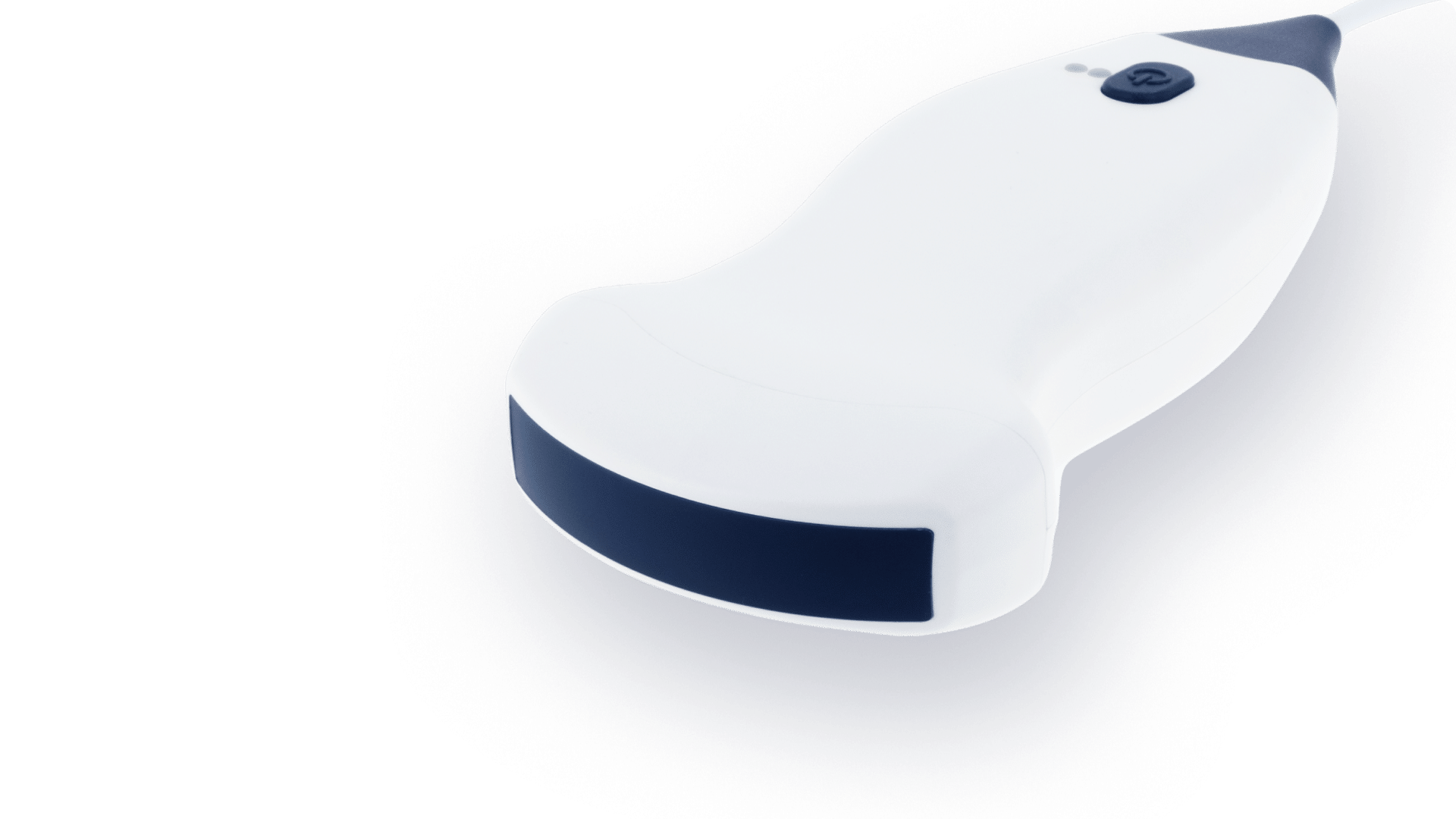

Your companion hardware

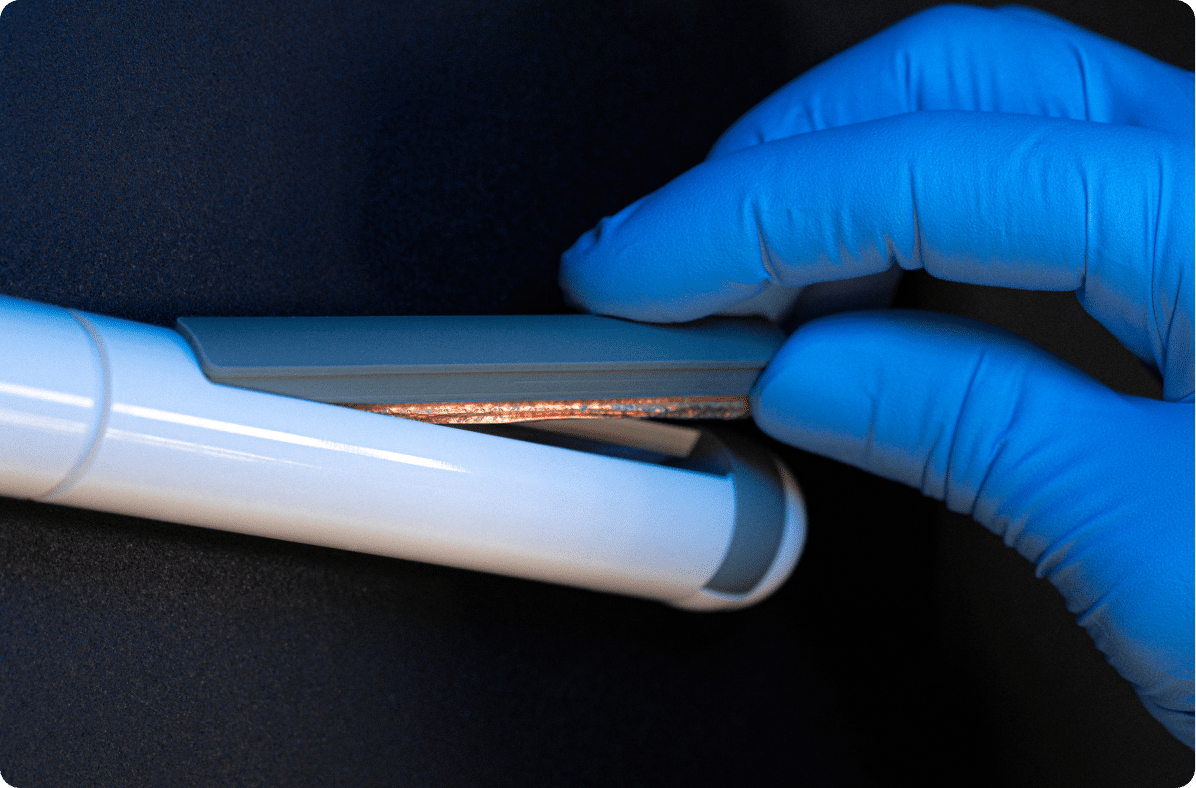

The OEM USB probe is an advanced ultrasound engine featuring state-of-the-art front-end electronics, including 128 transmit and 64 receive channels.

This device is built for high efficiency in a compact form, incorporating sophisticated power management and monitoring to maintain low power usage below 6W, ideal for portable and small-scale applications.It is equipped with an FPGA for refined ultrasound beamforming and includes a durable, high-capacity battery to support extended use.

It facilitates easy and effective connectivity with a USB-C interface, ensuring straightforward integration into various setups.

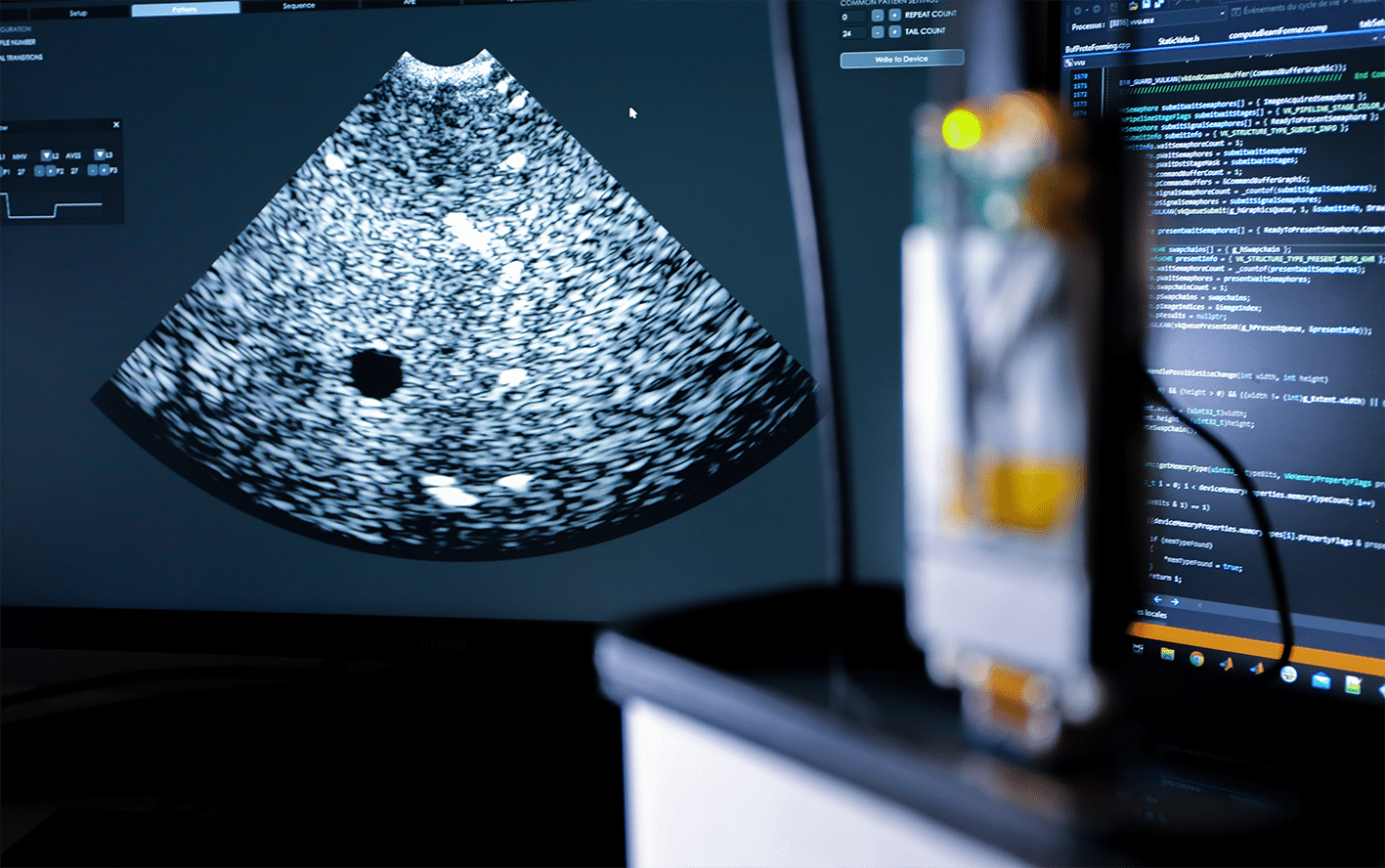

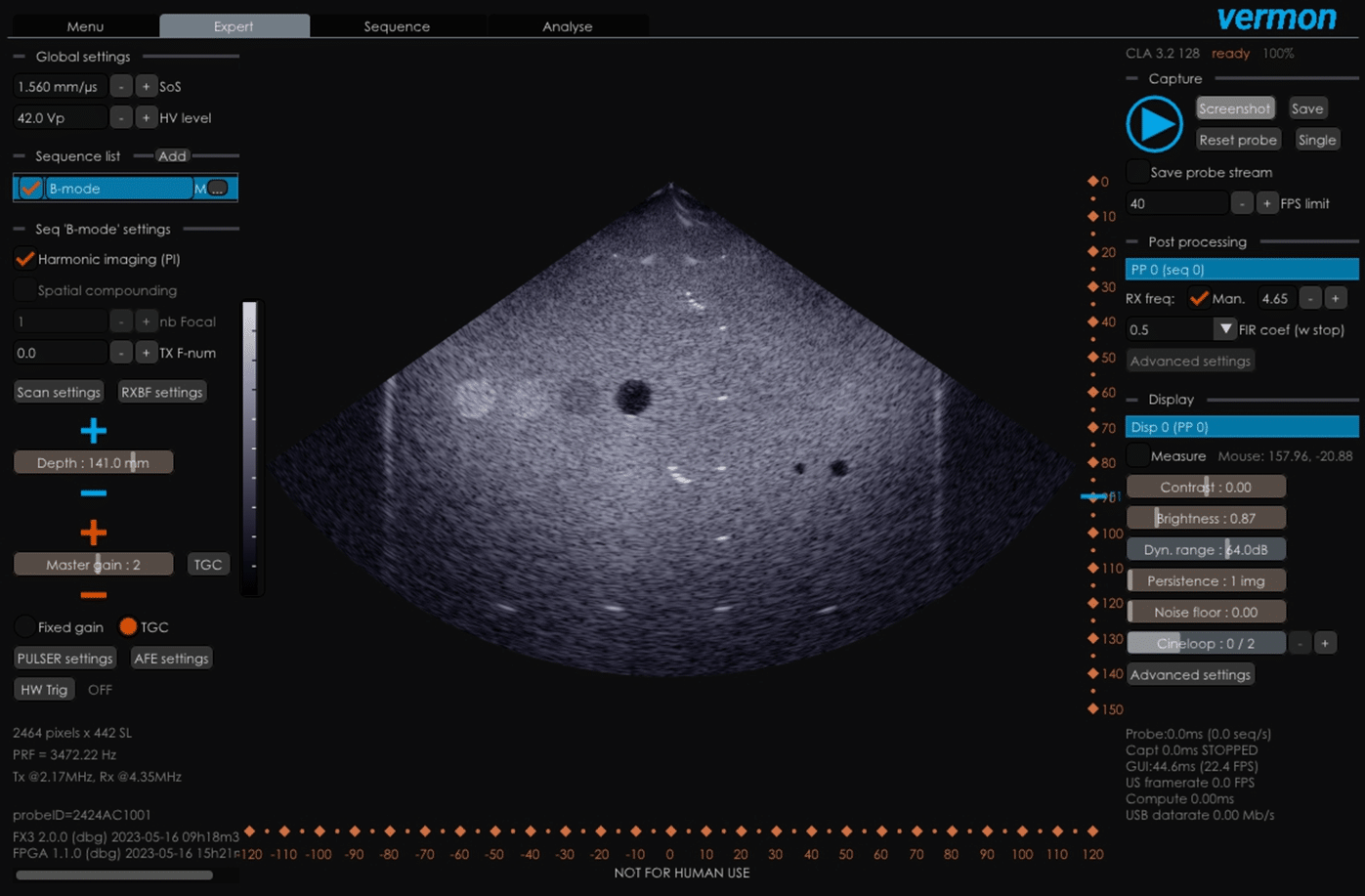

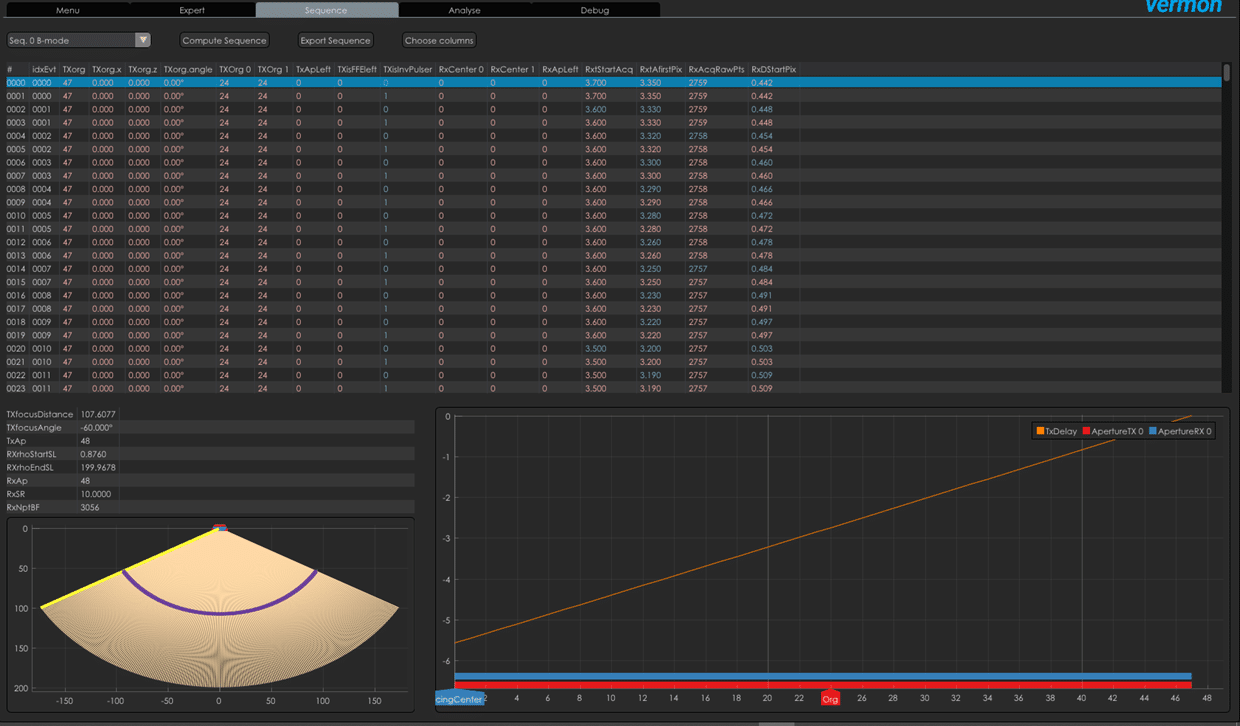

Pulsarus™ - Our software solution fully customizable

Our OEM USB Probe comes equipped with Pulsarus™, a software development kit that utilizes open-source, cross-platform libraries, granting you low-level control over the probe’s embedded electronics.

This ensures maximum flexibility in developing your applications and establishing your early proof of concept.

Pulsarus™ enables you to customize the USB Probe hardware platform for your specific end applications by offering:

- In-depth and user-friendly hardware control

- The ability to define custom ultrasound sequences

- GPU-based scan conversion and image post-processing

Get access to unaltered, unfiltered RF data!

Shaping the future of robotic surgery and therapy

Our innovative solution is crafted to expedite the development of instrumental Proofs of Concept, extending far beyond conventional diagnostic imaging.

This approach unlocks new possibilities in medical technology, especially in ultrasound applications such as robotic surgery, guided therapy, surgical procedures, biomarker measurement, AI and quantitative imaging, and ultrasound navigation and guidance.

We are committed to turning your ultrasound concepts into tangible realities.

Key benefits of our solution

Integrating our OEM USB Probe and Pulsarus™ into your development workflow brings a host of benefits:

- Rapidly define your product’s architecture with clear demonstrative examples and rapid proof-of-concept phase.

- Accelerate your software development timeline with our ready-to-deploy firmware and extensive SDK.

- Swiftly outline your product roadmap and enhance your competitive position.

Vermon's expertise and support

Vermon supports your development every step of the way; from idea, to early prototyping, industrialization and large-scale manufacturing – including quality and regulatory compliance validation.

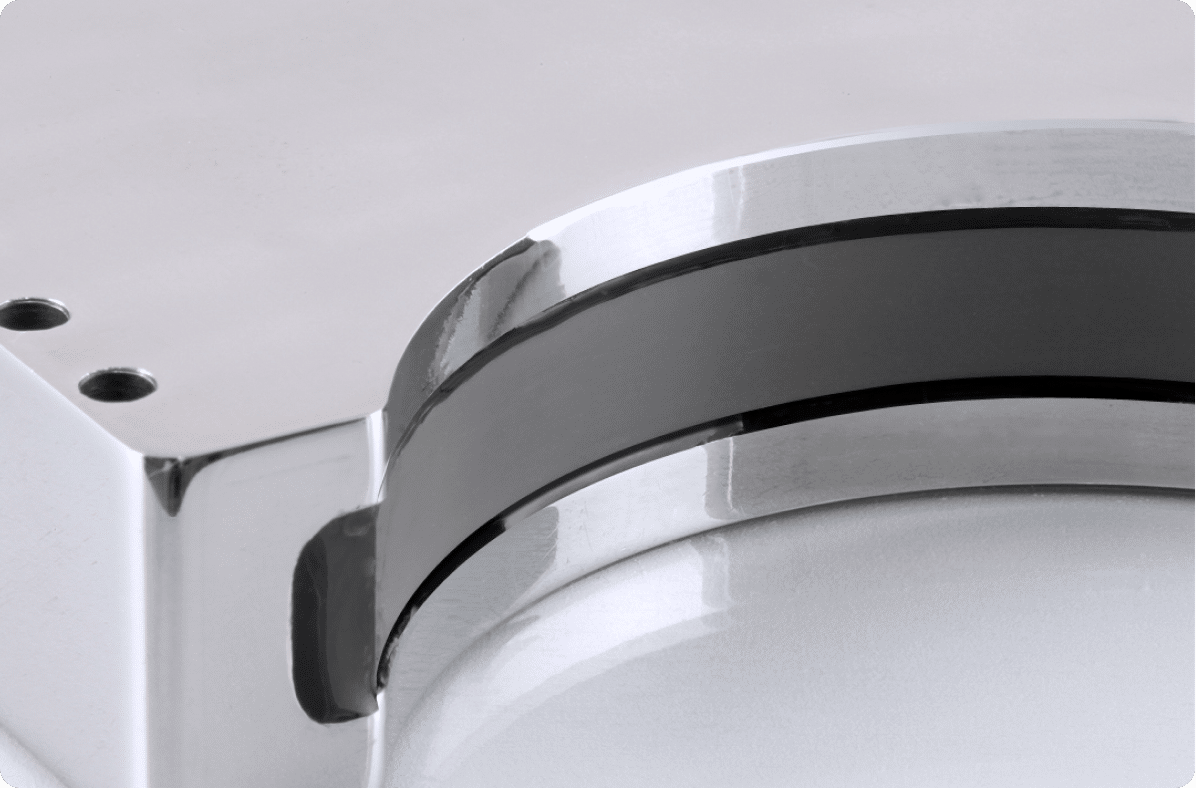

As your ultrasound expert partner, we can develop tailored solutions to match your product requirements and specifications – such as transducers topologies, electronic architecture, and integration into your hardware and software environment.

Recommanded probes:

OEM USB Probe – 2.75MHz – 80 elts

PA 2.75/80-DKPOC

-

Center Frequency 2.75

-

Number elements 80

-

Pitch 0.24

-

Radius curvature N/A

-

Transverse aperture 14

-

Focal Depth 80

OEM USB Probe – 3.5MHz – 128 elts

CLA 3.5/R50/128-DKPOC

-

Center Frequency 3.5

-

Number elements 128

-

Pitch 0.45

-

Radius curvature R50

-

Transverse aperture 13

-

Focal Depth 80

OEM USB Probe – 8.5MHz – 128 elts

LA 8.5/128-DKPOC

-

Center Frequency 8.5

-

Number elements 128

-

Pitch 0.3

-

Radius curvature N/A

-

Transverse aperture 4

-

Focal Depth 20