Facilities

Our Industrial Facilities

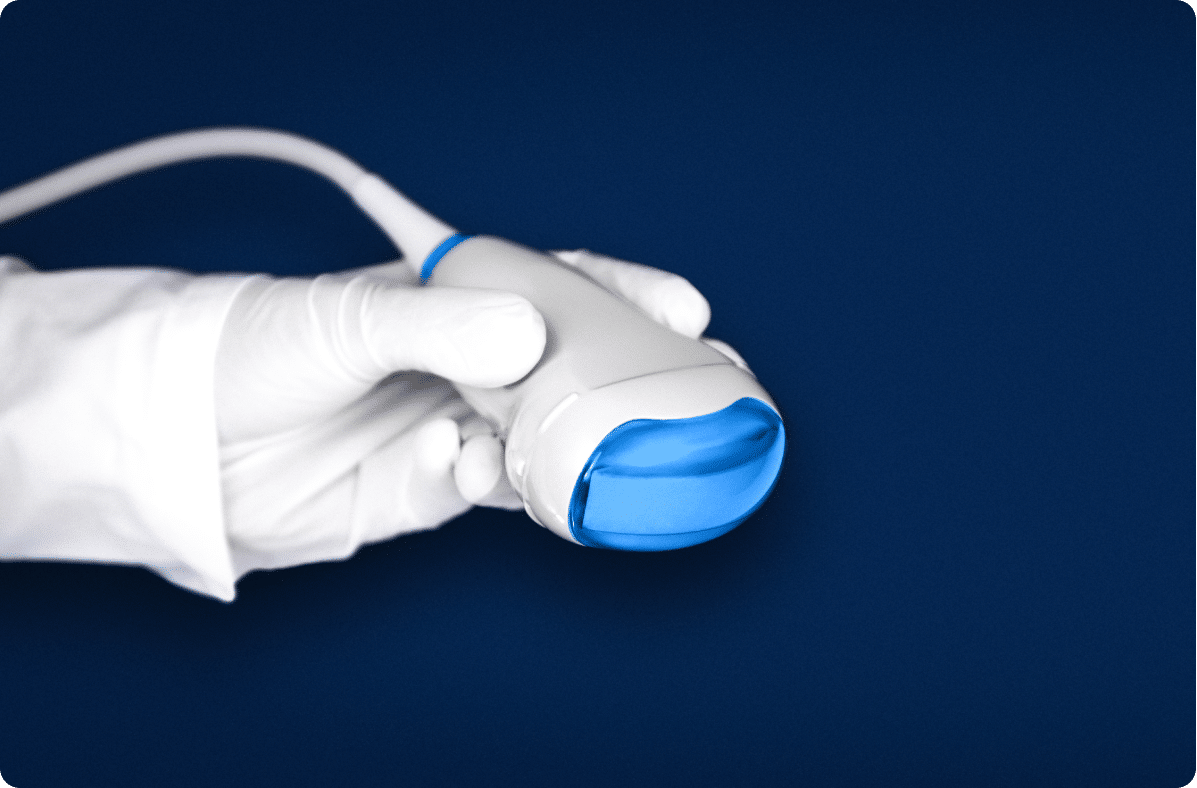

At Vermon, our french industrial facilities are located in Tours, in close proximity to our headquarters, where our R&D and engineering teams develop, technically refine, and industrialize prototypes that will become tomorrow's mass-produced products.

Within our walls, we have all the necessary equipment for ultrasound probe manufacturing.

200

Manufacturing Collaborators

10

Assembly Lines

7000 m2

on 3 production sites

98%

Service Rate

Supply chain Mastering

From raw materials to final integration, nearly 90% of the production process is conducted in-house.

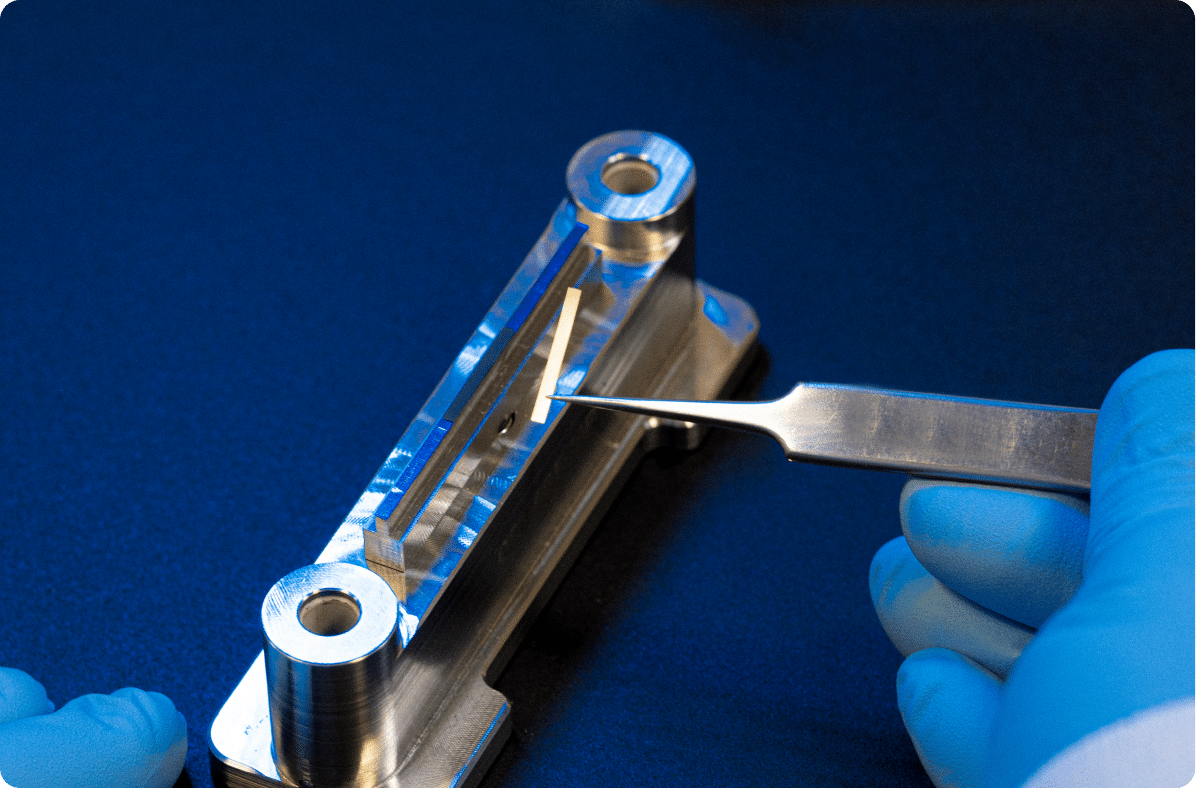

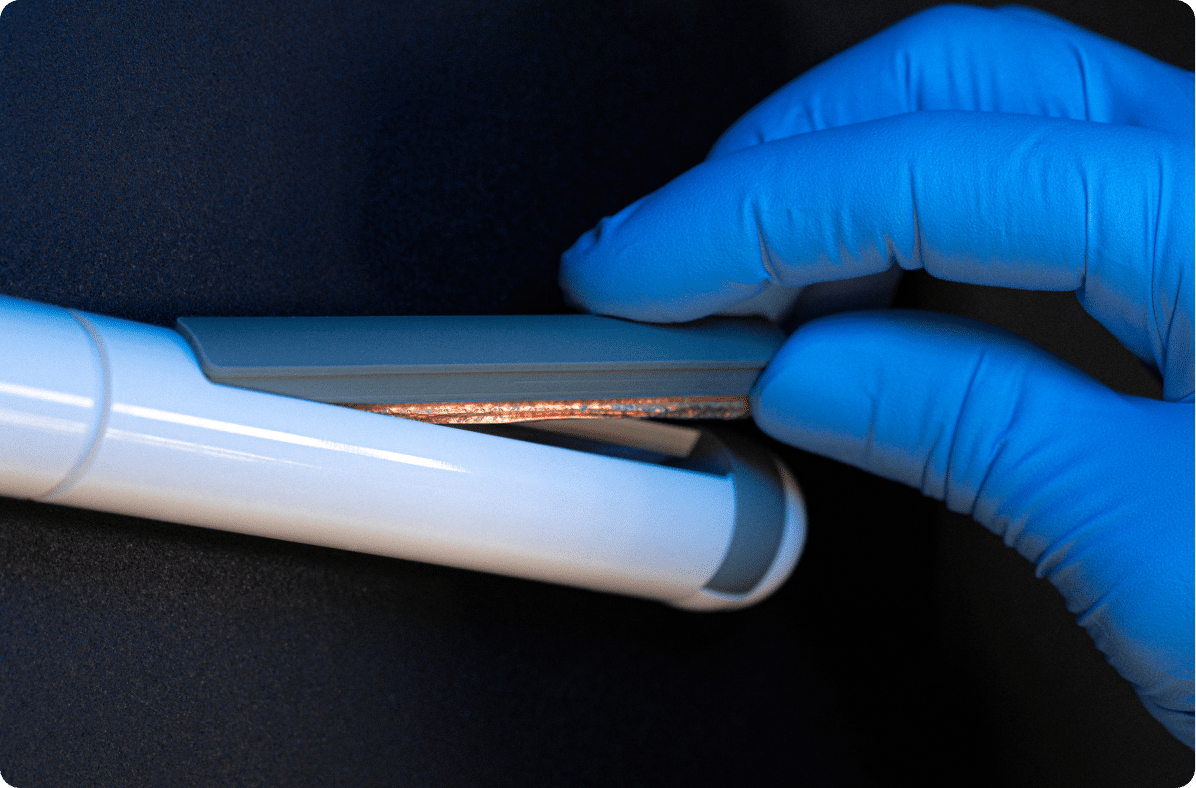

At the heart of our ultrasound probes lie the active and passive elements, meticulously crafted within our workshops equipped with state-of-the-art machinery specially designed to meet our client’s evolving needs.

All manufacturing lines, staffed by meticulous collaborators, are equipped with internally developed assembly and quality control tools through our mechanical and electronic workshops, enabling Vermon to master its production chain.

Manufacturing Lines

Vermon boasts 10 manufacturing lines within its premises.

These include the production of active and passive elements, as well as acoustic, mechanical, electronic assembly, and testing lines for both medical and industrial applications. Additionally, a pilot line for prototype and pre-series production is housed within our facilities, capable of executing all stages of product assembly.

200 collaborators work on three production sites covering almost 7000 m², enabling the production of more than one hundred product references.

This organizational setup ensures mastery over our manufacturing processes, reflected in a service rate of 98%.

Acoustic Material Department Facilities

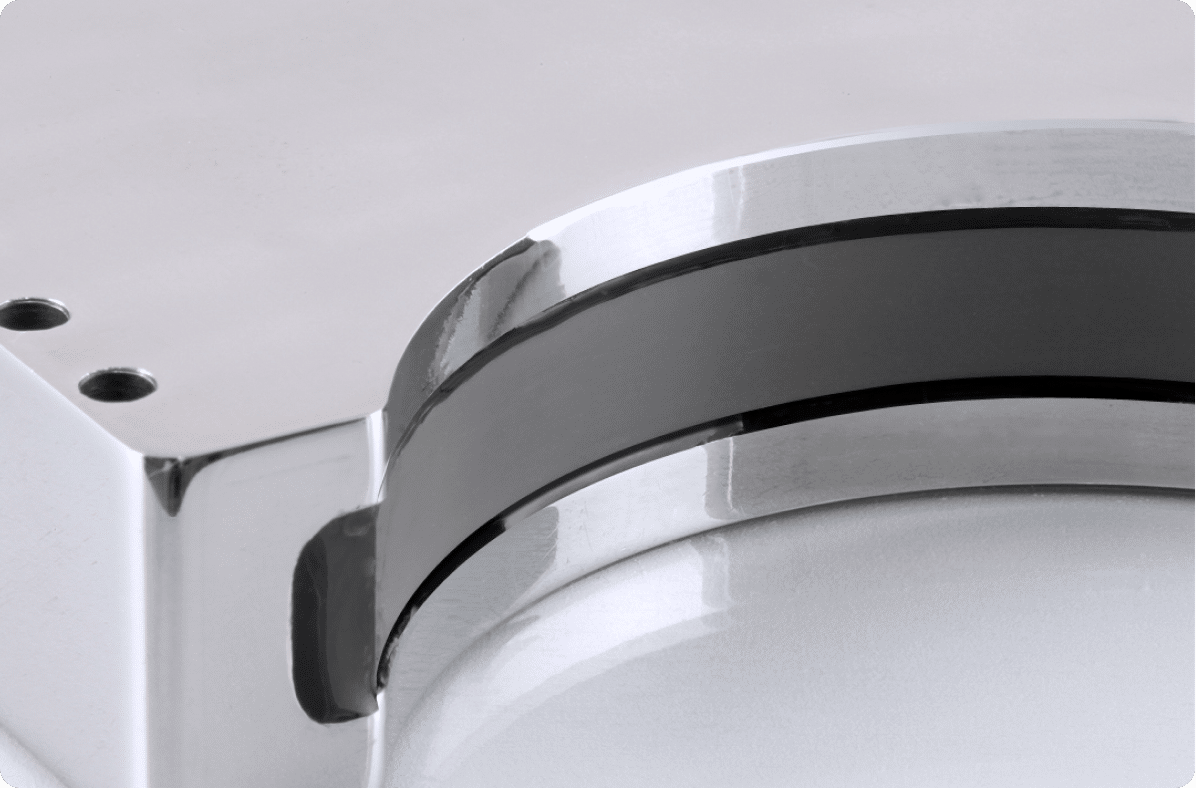

In the acoustic material production area, the core of our probes is manufactured.

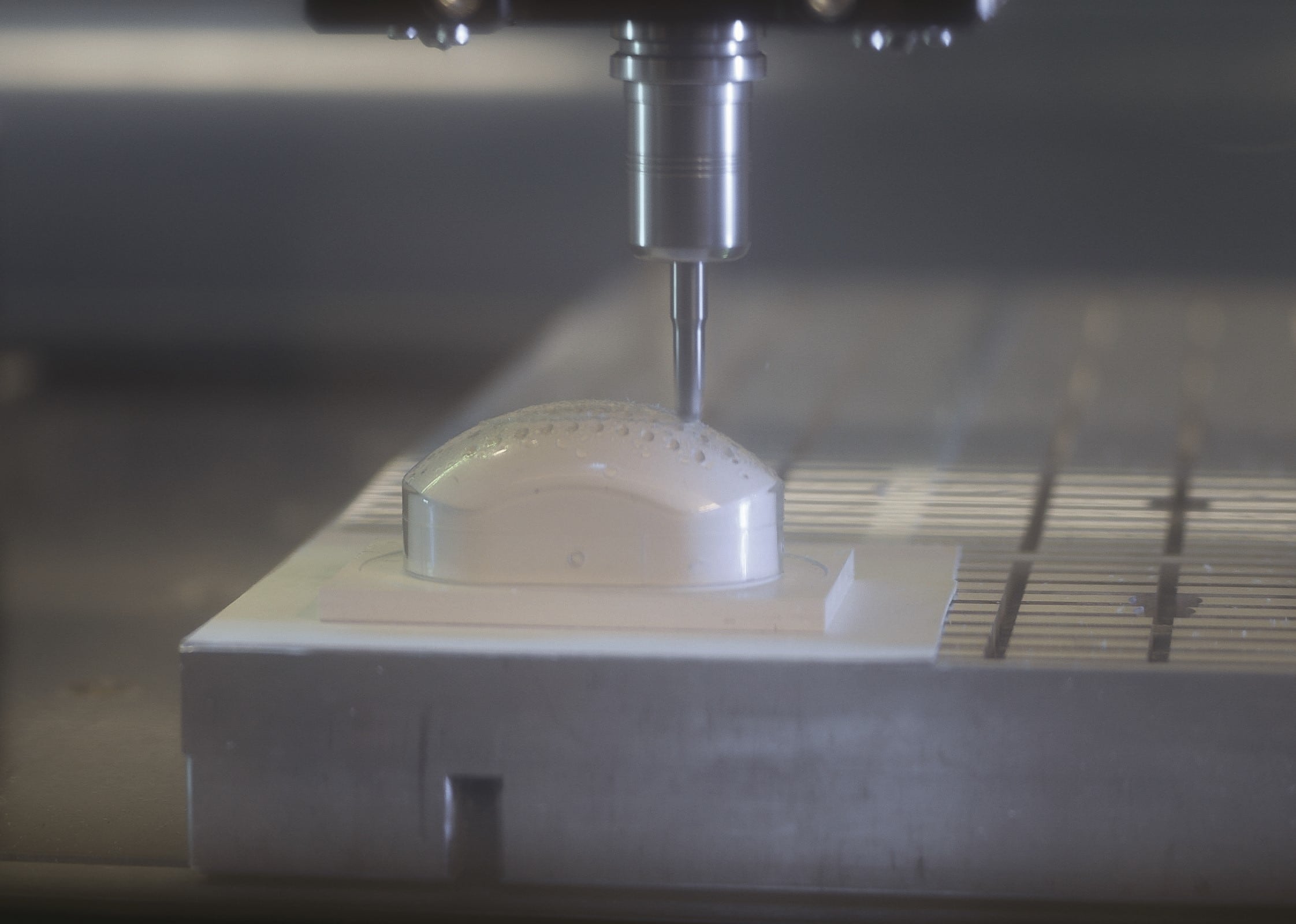

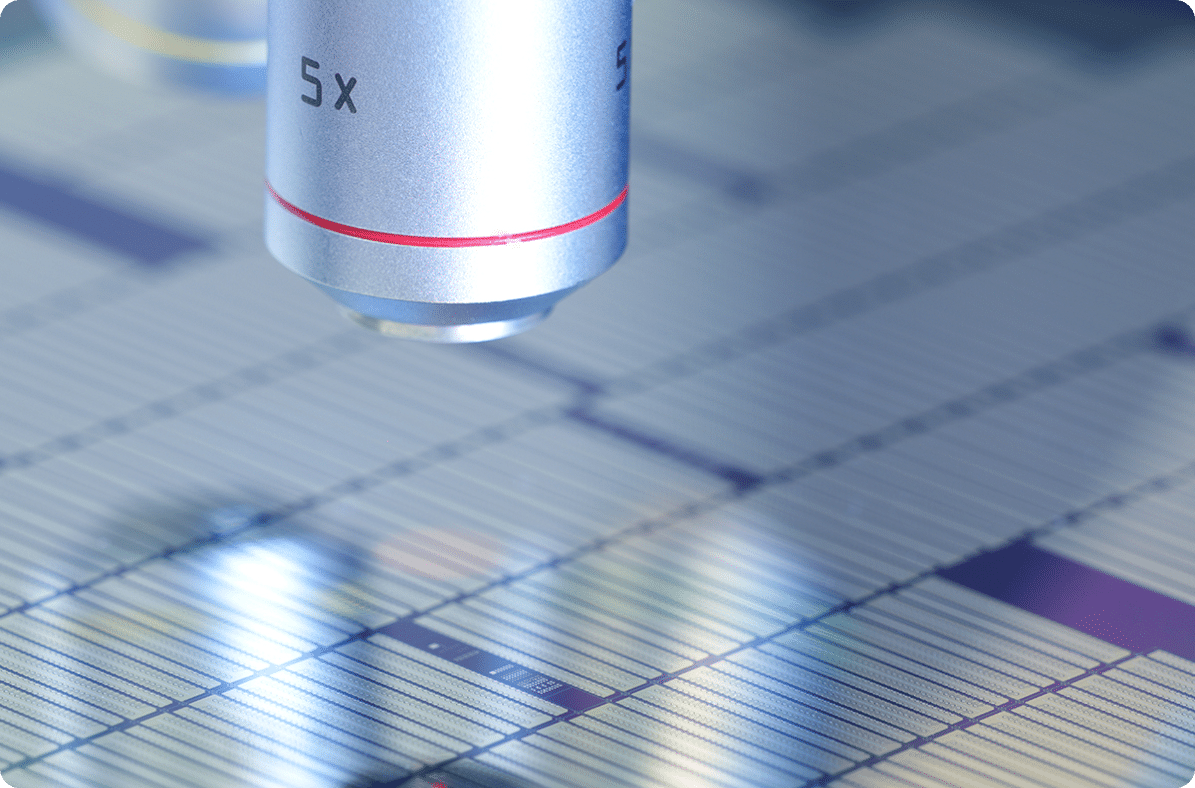

Spanning 400m², this space transforms piezoelectric materials into piezocomposites (the active element) and all acoustic materials using specialized machinery such as Automatic Dicing Saws, Automatic Surface Grinders, and PVD chambers.

It’s also here that passive elements are manufactured and assembled, ensuring the acoustic performance required to satisfy our clients’ needs. All active and passive elements undergo characterization before being assembled on the production lines.

The annual production capacity for piezocomposites is 24m², equivalent to 24 000 000 mm².

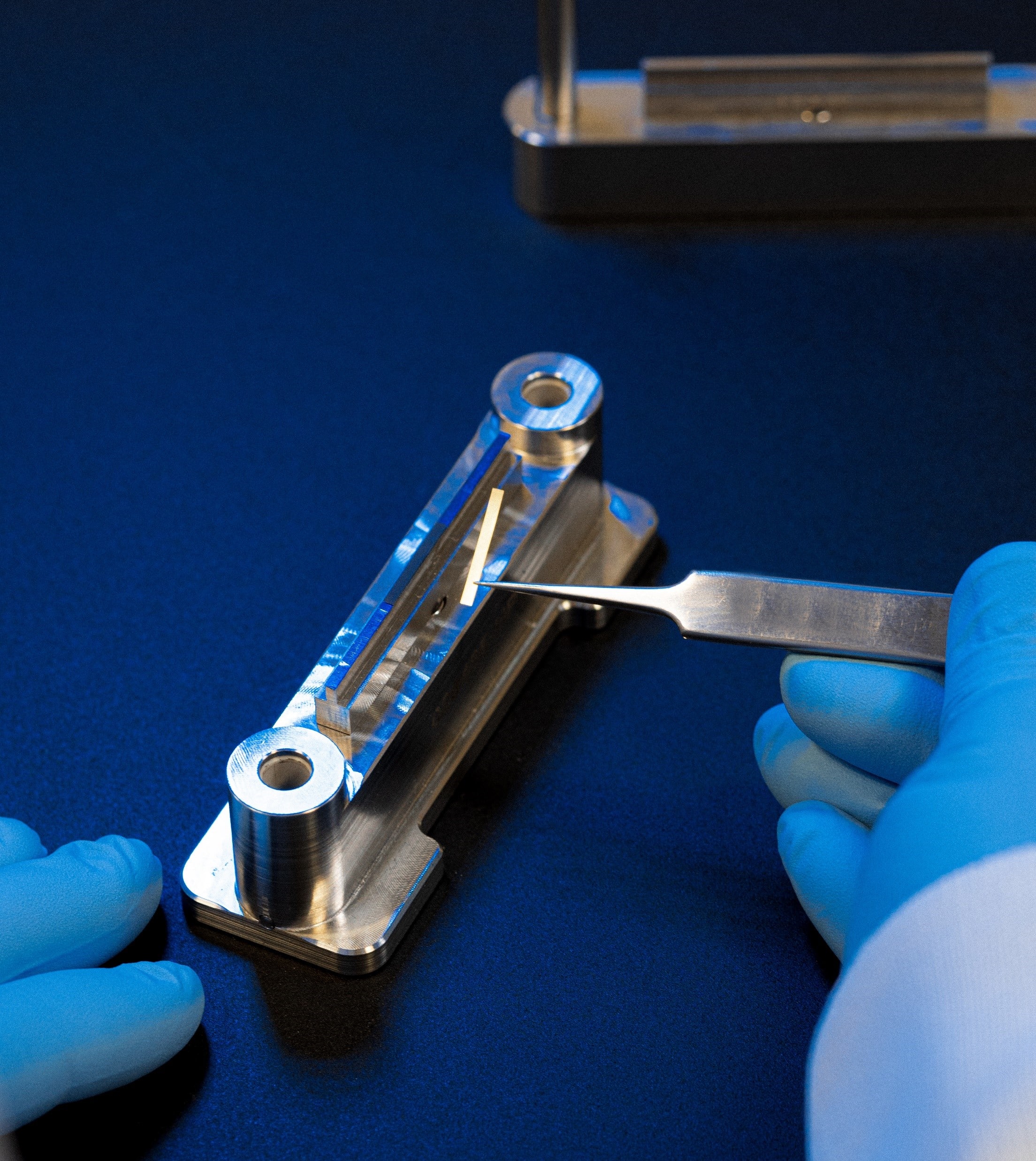

Mechanical Production Area

Covering an area of 70m², the mechanical workshop focuses on machining mechanical parts and assembly tools for our prototypes. Equipped with CNC milling, turning machines and 3D printing machines, this workshop enables Vermon to maintain agility in prototype manufacturing.