TransducerWorks: Customized Ultrasound Transducers

Established in 2007 in Centre Hall, Pennsylvania in the heart of the american ultrasound valley next to Penn State University, TransducerWorks is a part of the global Vermon Group since 2018.

Visit TransducerWorks' website

Established in 2007 in Centre Hall, Pennsylvania in the heart of the american ultrasound valley next to Penn State University, TransducerWorks is a part of the global Vermon Group since 2018.

Design and Manufacturing Excellence

TranducerWorks designs and manufactures custom, state-of-the-art ultrasound transducers for medical and industrial applications.

Its main driver is to be dedicated to improving the quality of life through the development of innovative ultrasound products.

Trailblazers in Ultrasound Technology

TransducerWorks was founded by a group of industry veterans with a bold vision: to revolutionize ultrasound technology.

Since then, they have grown strongly, adding to the team, creating thousands of transducers, and accumulating a portfolio of technology patents.

By heavily investing in cutting-edge machinery, they haven’t only increased their production capacity but also established a reputation for high-quality products and unmatched customer service.

A Team of Experts

At Transducer Works, strength lies in the team.

Comprising 90 dedicated employees, 20 specialize in Research and Engineering, all committed to developing high-quality products.

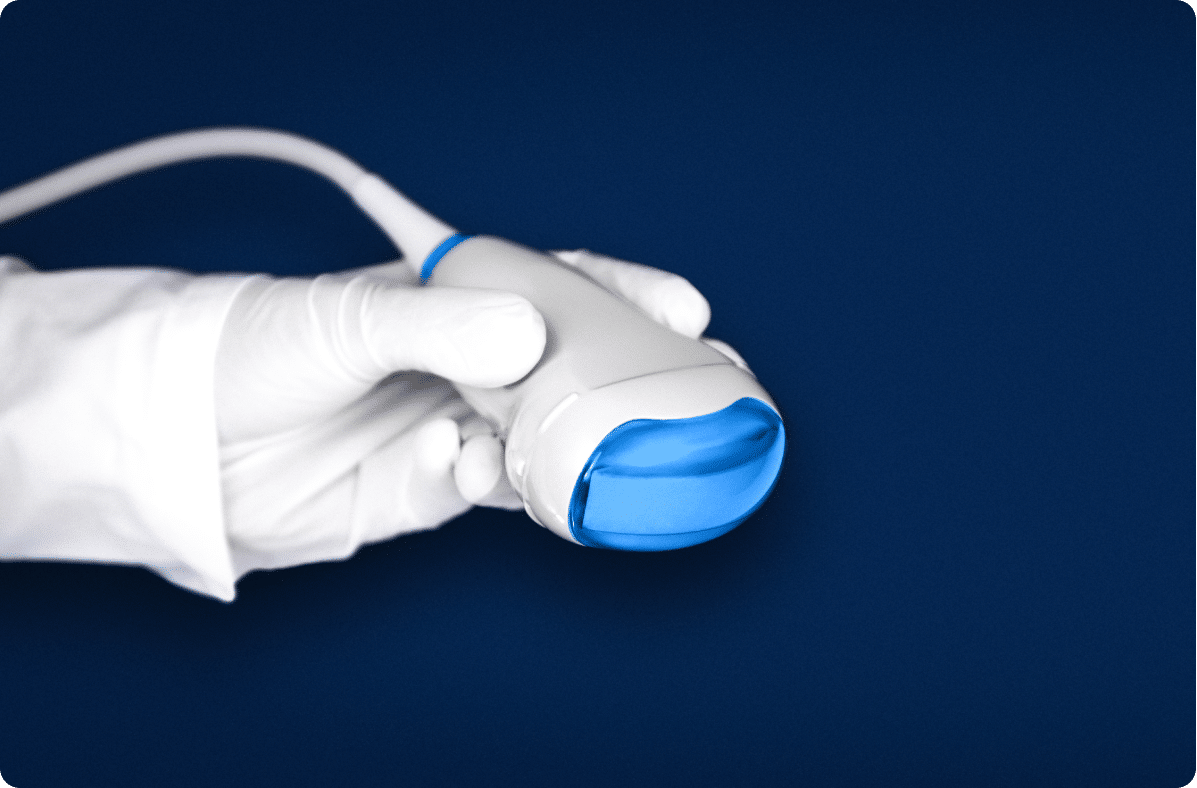

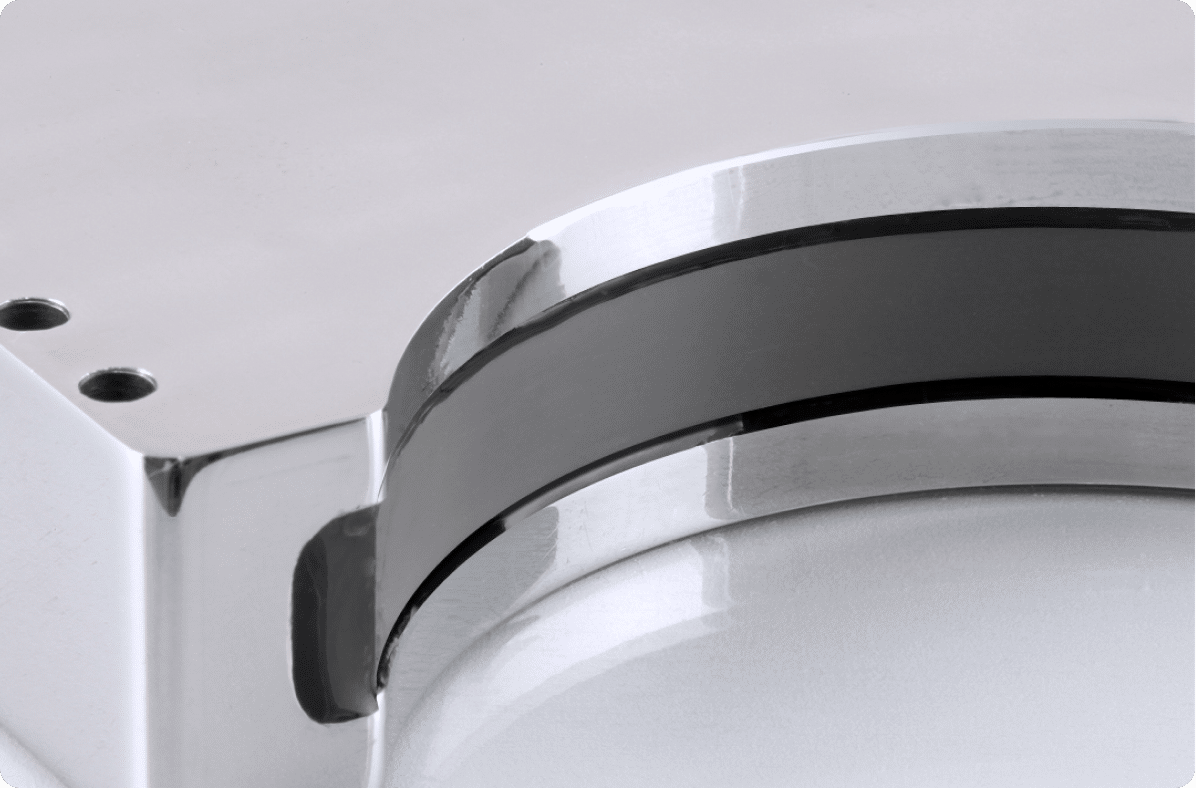

Custom-Built Ultrasound Transducers

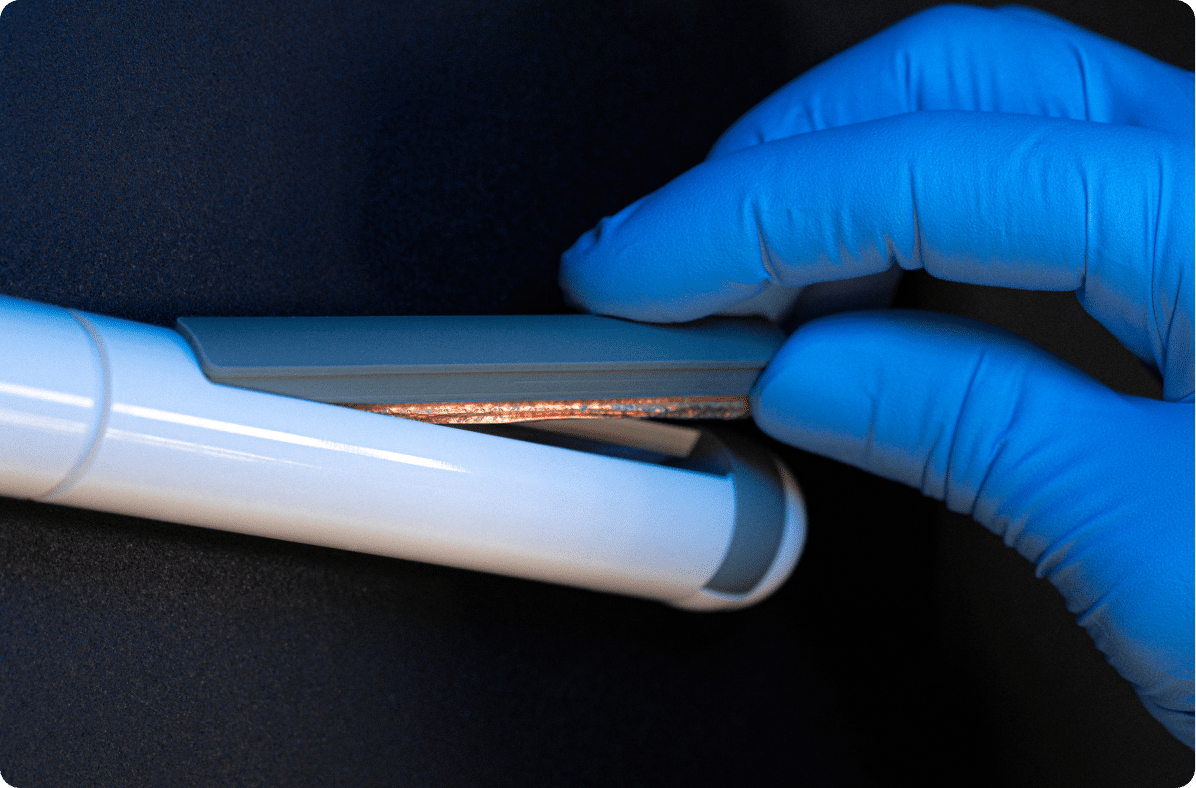

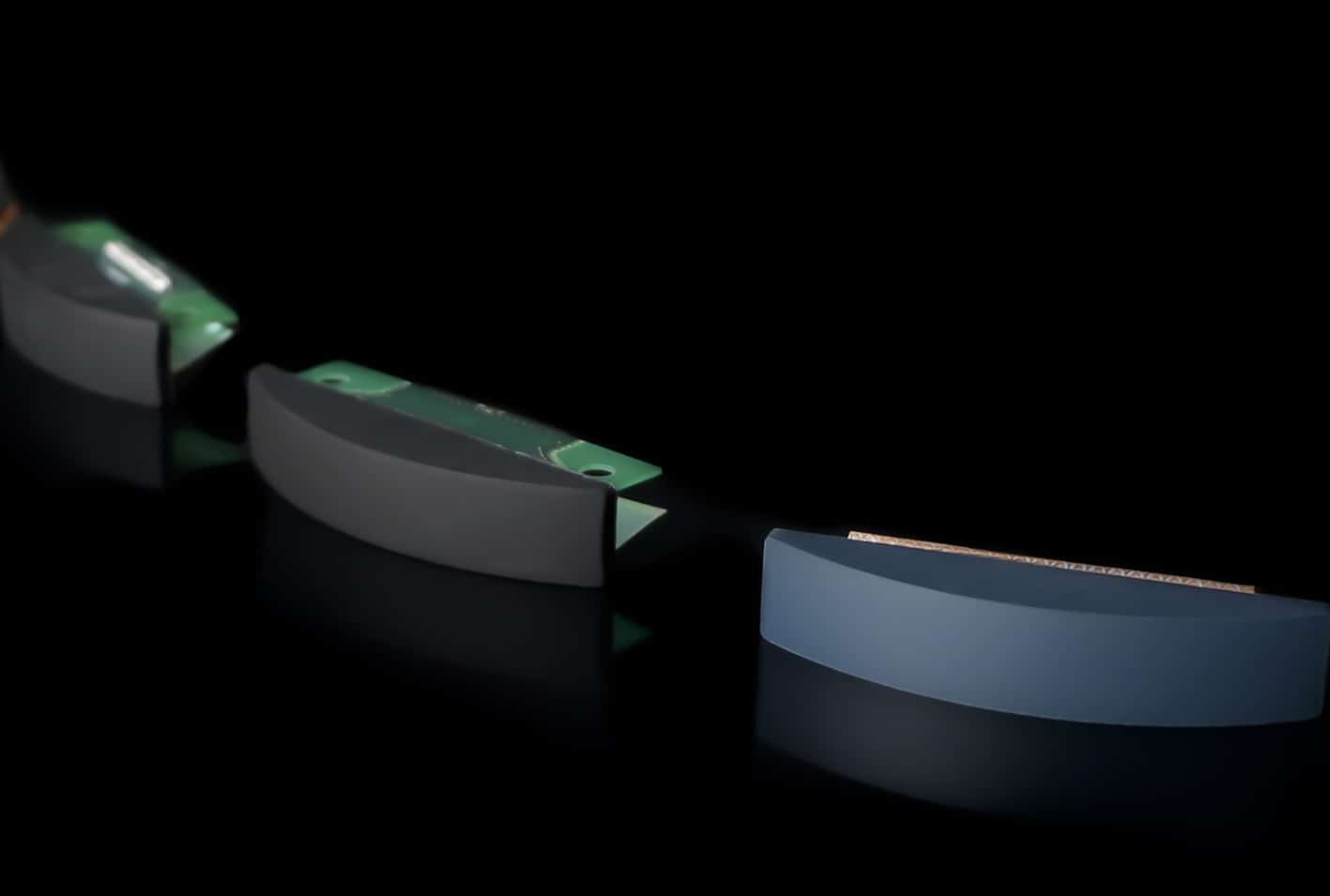

TransducerWorks benefits from years of experience in custom-building ultrasound transducers, including complex phased, curved, and linear arrays, as well as single-element or Doppler transducers, which sets them apart.

They design transducers to meet your specific requirements, whether it is developing complete arrays, including cable assembly and connectors, or just transducer arrays for integration into your own device.

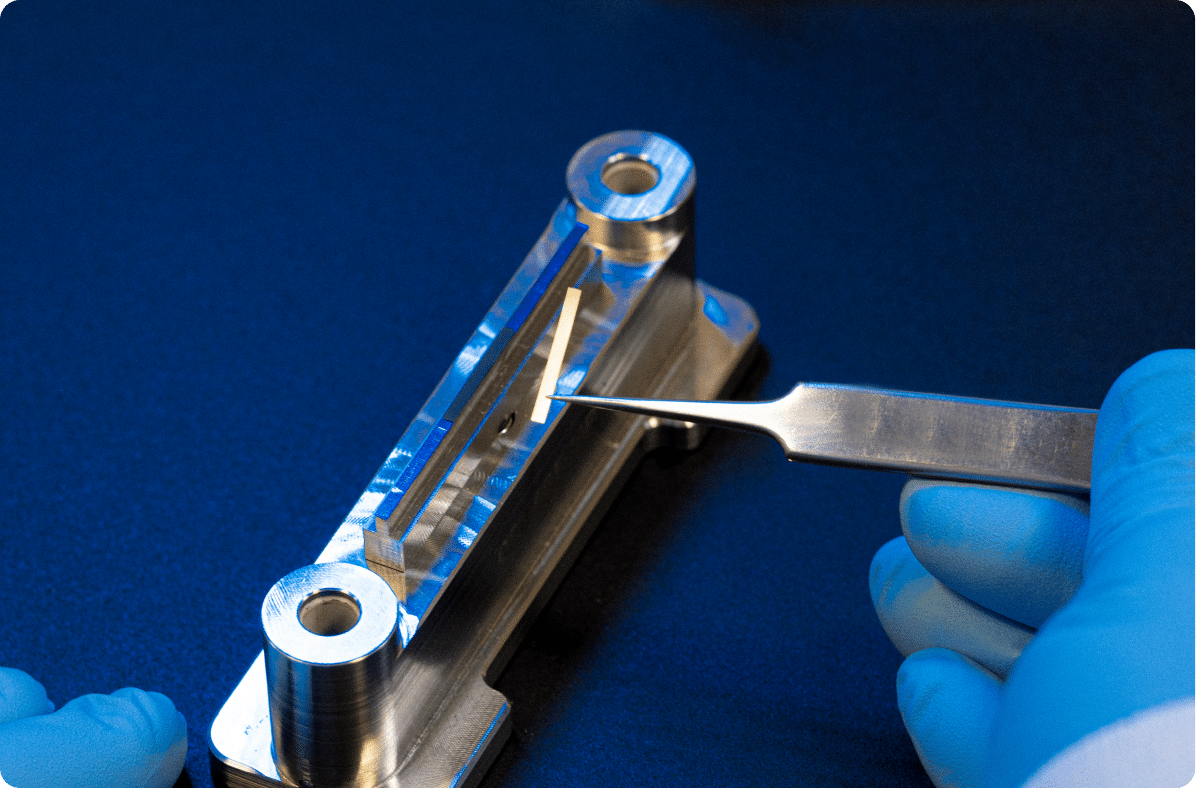

Onsite Manufacturing Facilities

Their manufacturing facilities, which include a full machine shop with several CNC machine centers, allow them to manage the entire production process in-house.

You don’t need to outsource prototyping or part building. Whether you need 5, 50, or more than 1000 transducers, TransducerWorks can fulfill your order in-house, ensuring a high level of quality.

Commitment to Quality

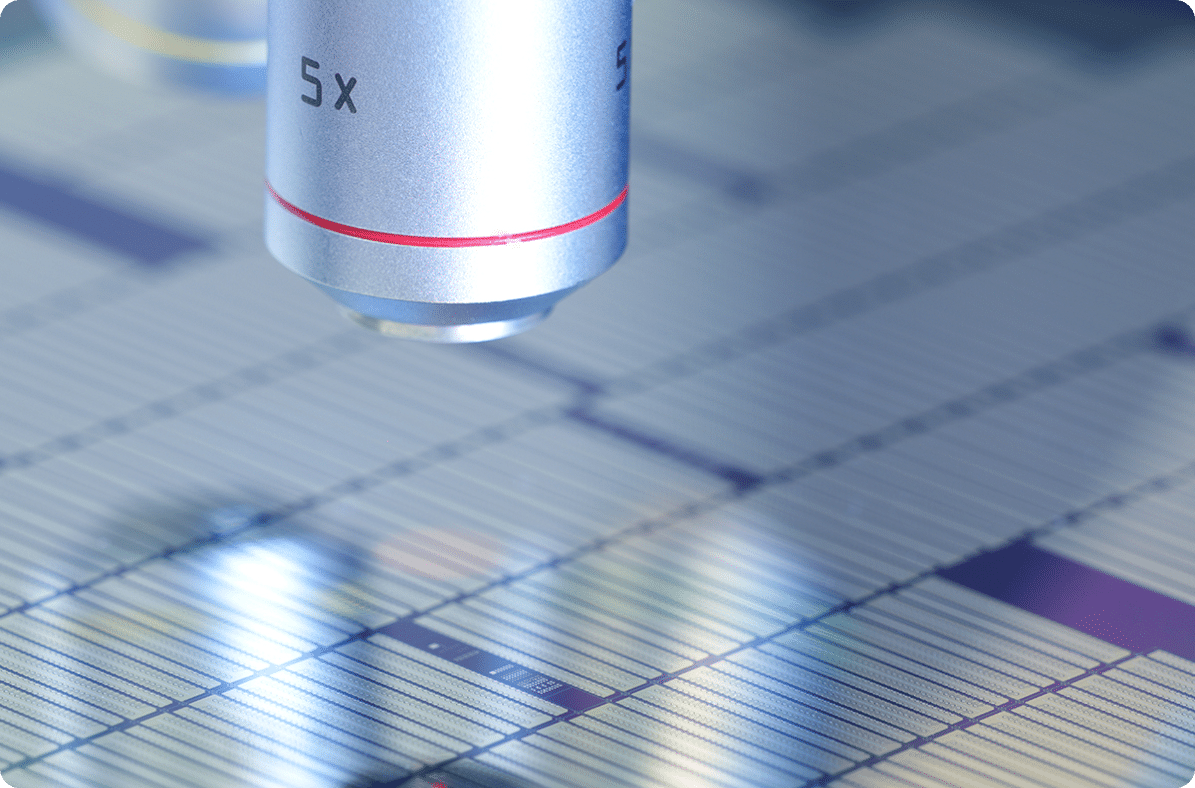

TransducerWorks ensure customer and regulatory requirements are understood and met, and a quality management system is established and maintained.

This dedication to quality is reflected in their ISO 13485 certification and efforts to meet their customers’ RoHS and REACH needs with individualized certificates.

TransducerWorks is a registered FDA manufacturing site.