PAUT Probes in Industries

NDT Solutions for Industry Applications

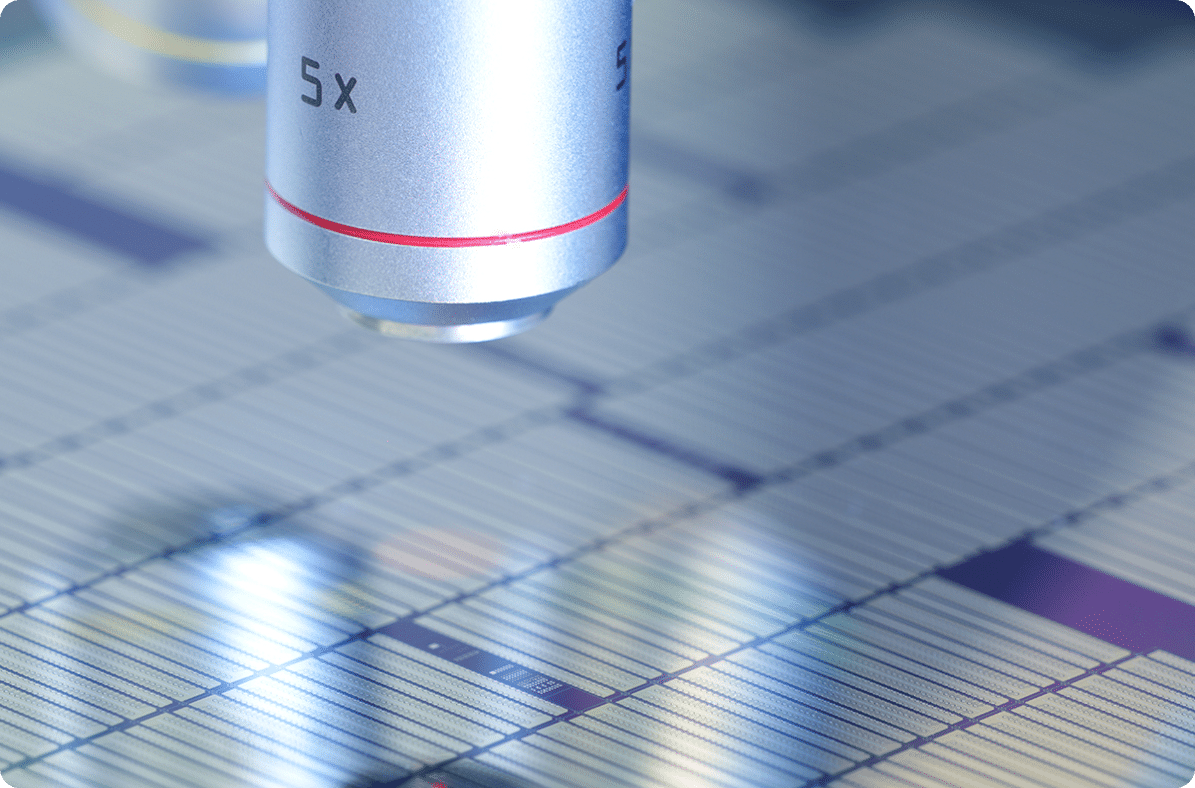

Non-Destructive Testing (NDT) with Phased Array Ultrasonic Testing (PAUT) probes is essential in maintaining the safety, integrity, and efficiency of operations across various high-stakes industries.

Our PAUT probes offer unparalleled precision in detecting flaws and ensuring the quality of critical infrastructure and components.

Oil & Gas

In the demanding environments of the oil and gas sector, the integrity of pipelines, storage tanks, and drilling equipment is paramount.

- Detect Corrosion and Erosion: Monitor and identify the early stages of material degradation.

- Inspect Welds: Ensure weld quality and compliance with safety standards.

- Measure Material Thickness: Accurately gauge the thickness of materials to prevent failures and leaks.

PAUT probes enhance NDT in Oil&Gas Industry by providing detailed cross-sectional imaging for more accurate flaw detection, rapid scanning for increased efficiency, and comprehensive coverage from a single setup point, reducing downtime and operational costs.

PowerGen

Power plants require constant monitoring to maintain operational standards and safety.

PAUT probes are utilized in various facets of power generation, including nuclear, thermal, and renewable energy sectors, to:

- Assess Critical Components: Turbines, boilers, and steam pipes are inspected for defects that could lead to catastrophic failures.

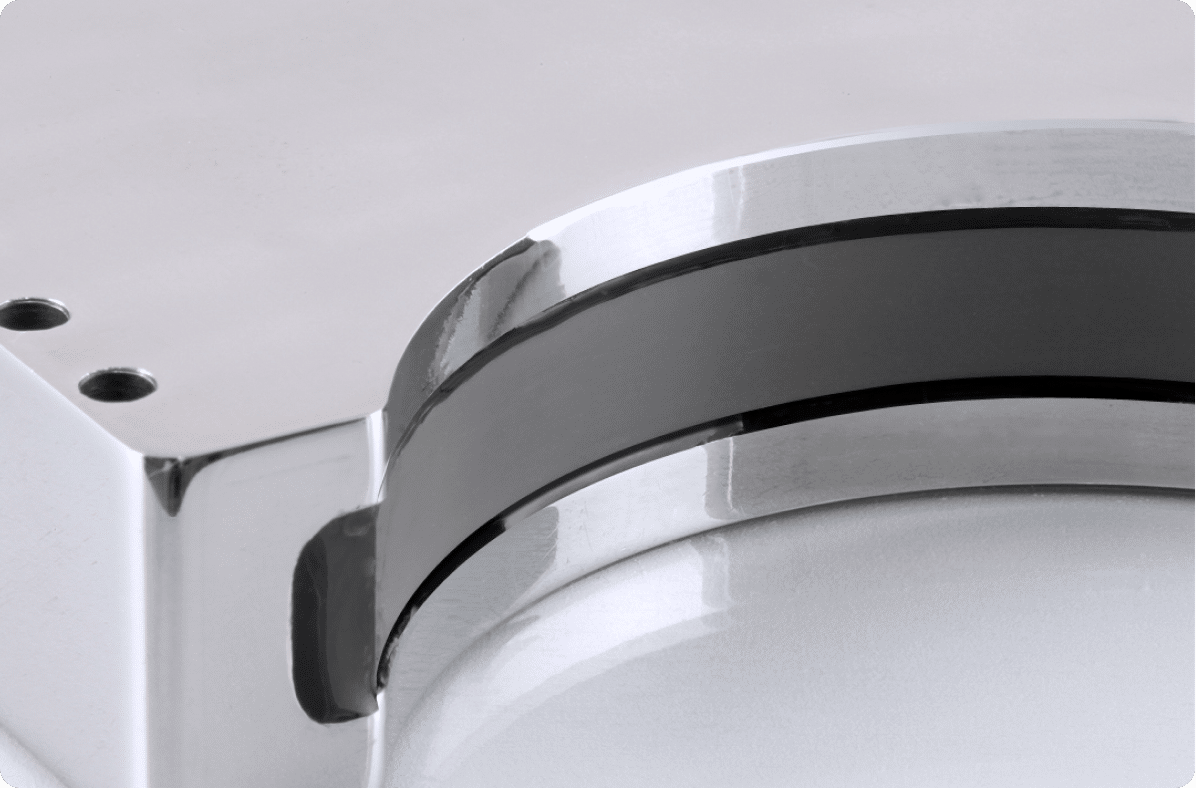

- Surface Crack Detection: PAUT probes enhance the detection of surface and subsurface cracks in complex geometries.

PAUT probes offer high sensitivity for detecting minute defects in critical components, versatility across various materials and complex geometries, and produce extensive data for thorough analysis and predictive maintenance in power generation.

Aerospace

The aerospace industry benefits significantly from the advanced capabilities of PAUT probes, ensuring aircraft and spacecraft safety through:

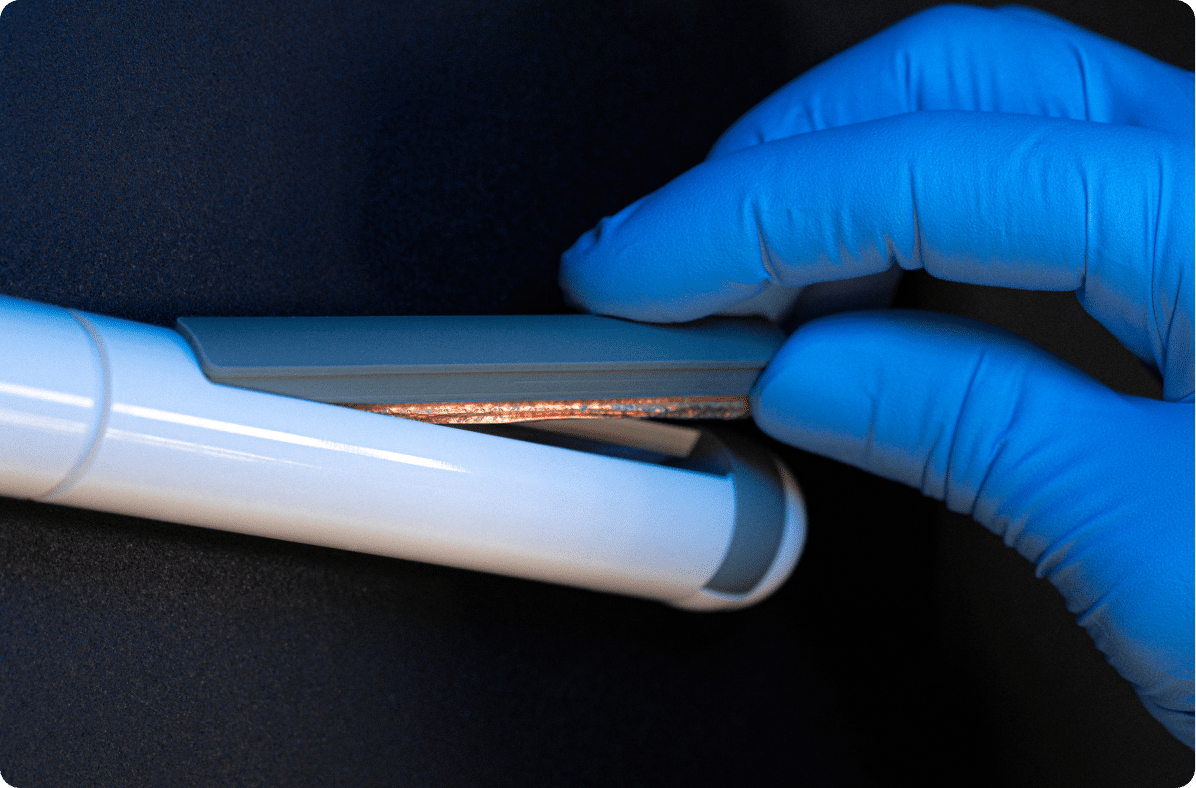

- Composite Material Inspection: Critical for detecting damage in composite materials used extensively in aerospace.

- Turbine Blade Integrity: Inspect and monitor turbine blades for fatigue cracks and other wear-and-tear.

- Aircraft Skin Examination: Identify structural issues within aircraft skins, critical for ensuring the safety during flight.

PAUT probes ensure precision and reliability with high-resolution imaging for aerospace components, adeptly handles complex geometries, and enables early detection of potential failures to uphold stringent safety standards.

Transportation

PAUT is a key tool for inspecting maritime vessels or rails :

- Hull and Weld Inspection: Ensure the integrity of ship hulls and the quality of welds, crucial for maritime safety.

- Rail Inspection: Detect irregularities and wear in railway components, preventing failures in rail operations.

PAUT probes enhance transportation sector inspections with detailed capability to detect often-missed flaws, rapid deployment for time-sensitive applications, and durable, adaptable equipment suited for harsh environments.

Vermon NDT

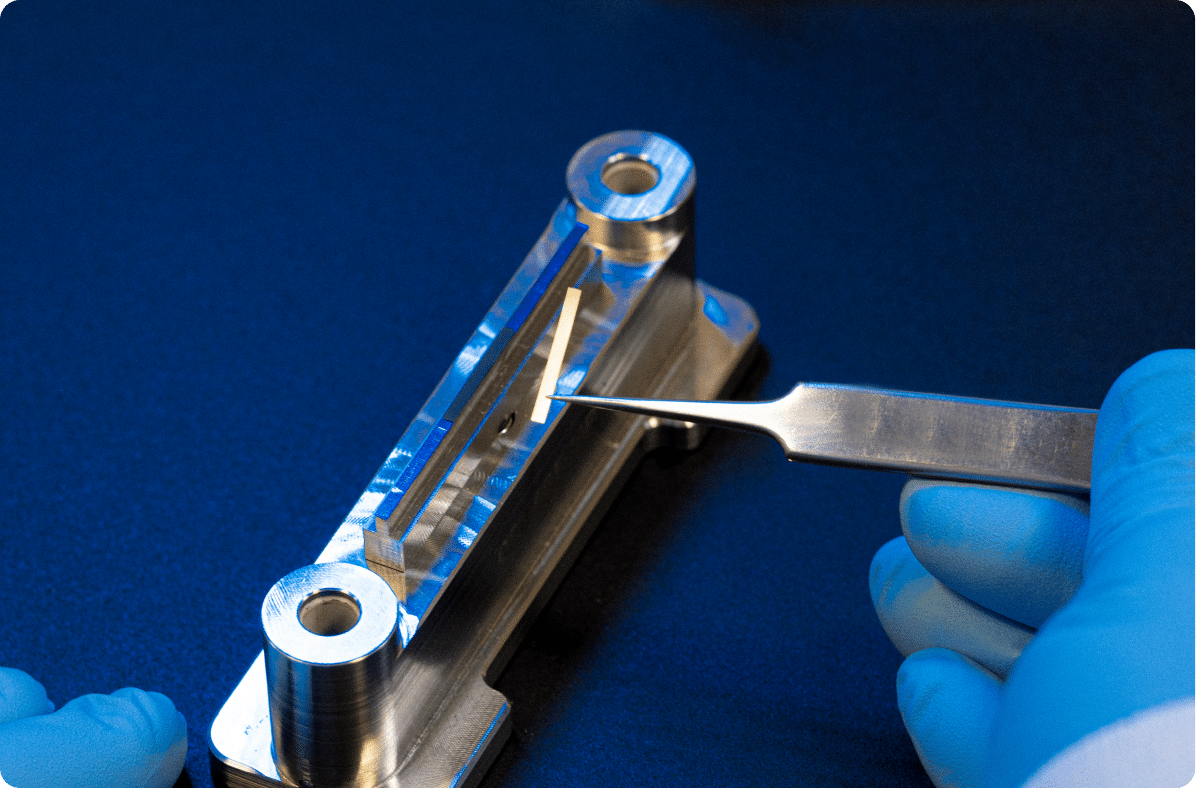

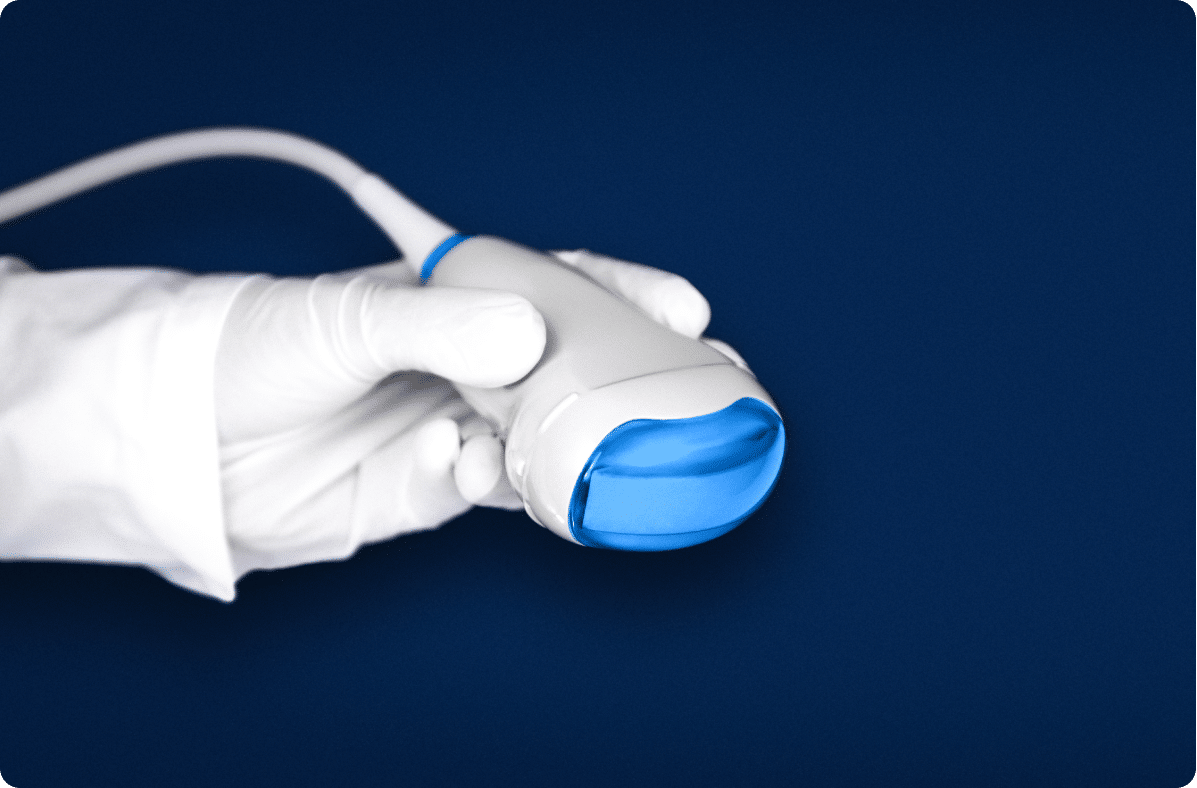

At VERMON NDT we offer different types of standard and custom probes that are utilized to address specific needs and challenges of each industry.

To learn more about our NDT products, visit our dedicated website.